Wearable Technology and tesa Tape – a Partnership To Watch

As the global market for wearable technology continues to grow, tesa® 612xx High Performance Tapes will play an important role in the design and production of these futuristic devices.

As the global market for wearable technology continues to grow, tesa® 612xx High Performance Tapes will play an important role in the design and production of these futuristic devices.

Technologies

Close cooperation between tesa and wearable OEMs ensures that our tapes meet the specific adhesive bonding requirements of wearable tech.

As wearable devices continue to grow faster, smaller, and more affordable, consumers are increasingly paying attention to this new personal technology trend. From fitness trackers and smart watches to smart glasses and virtual reality glasses, this category of wearable tech is generating some of the biggest buzz in the tech industry. With so many endless possibilities, wearables could be the biggest new mainstream innovation since the smartphone. Time will tell, but the market for devices you can wear on your wrist, face, or literally anywhere is expected to grow at a fast pace over the next few years – and tesa will play a critical role in this exciting technological revolution.

According to analyses performed by international accounting and auditing firm PricewaterhouseCoopers (PwC), the worldwide market for wearables was valued at 6.3 billion euros in 2015 and is expected to grow by 21 percent per year through 2018. German industry association Bitkom expects the European market to see 24 percent annual growth, climbing to as much as 8.8 billion euros in 2018, and the PwC forecast is even more optimistic, predicting an average annual growth of 25.2 percent between now and 2018. Although smart watches will remain the main source of wearables revenue for the next several years. there are a quite a few different categories of wearable technology that have consumer potential. These categories include augmented reality glasses, smart clothing and jewelry, and implantables.

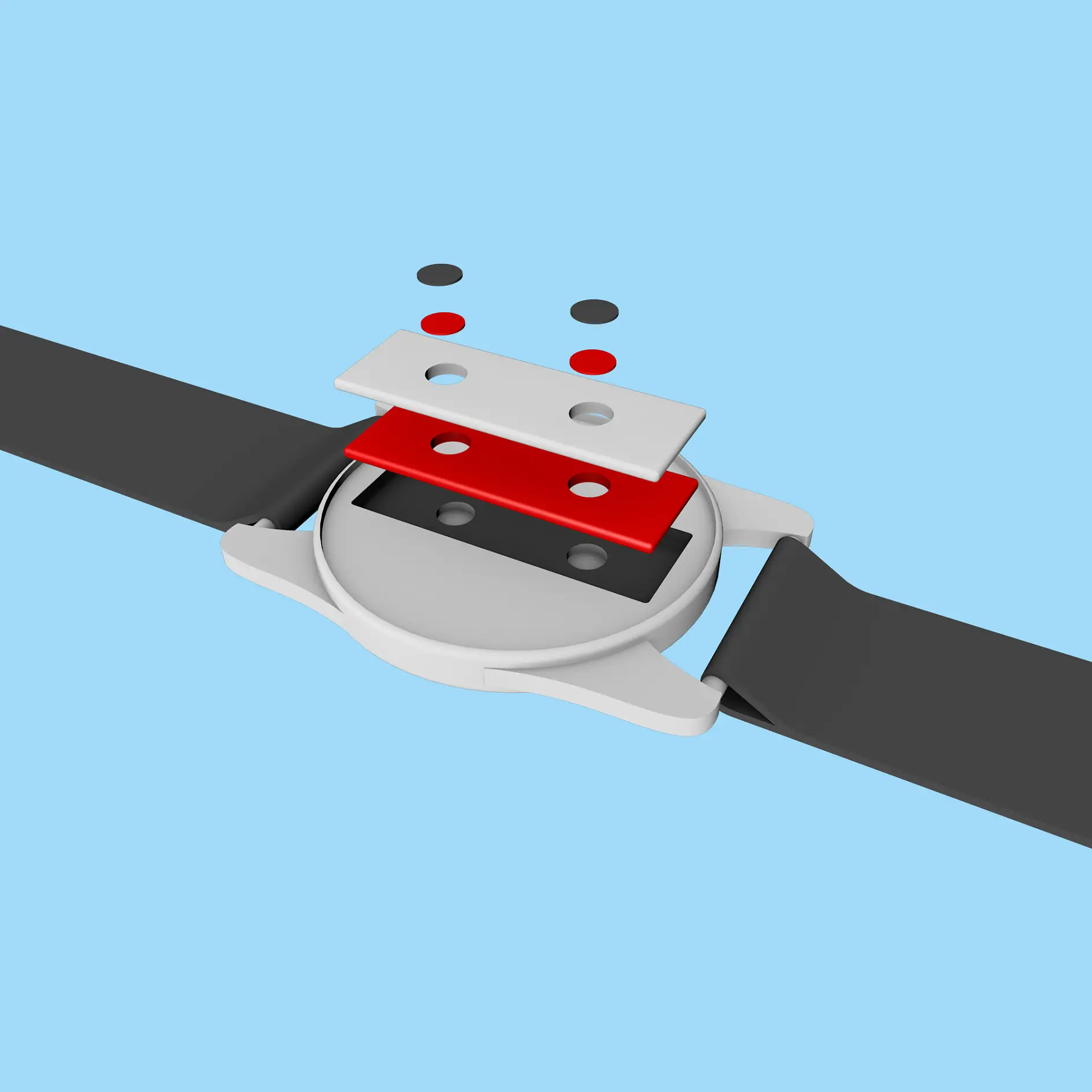

Since wearables are constantly in motion, the bonding tapes used for both internal and external components must offer high adhesive strength and shock resistance. Since they are in such close contact with the body, wearable devices – even when considered “waterproof” – are exposed to various biological and chemical substances, including sweat, perfume, sunscreen, bug spray, and soap. Although the tape does not have direct skin contact, particles of these substances, some of which are corrosive, can penetrate inside the wearable device through tiny gaps and potentially dissolve the adhesive bond. For this reason, tesa® 612xx High Performance Tapes, which includes six double-sided tapes ranging in thickness from 50 to 300 micrometers, have embedded “antibodies” to resist exposure to chemicals and other substances.

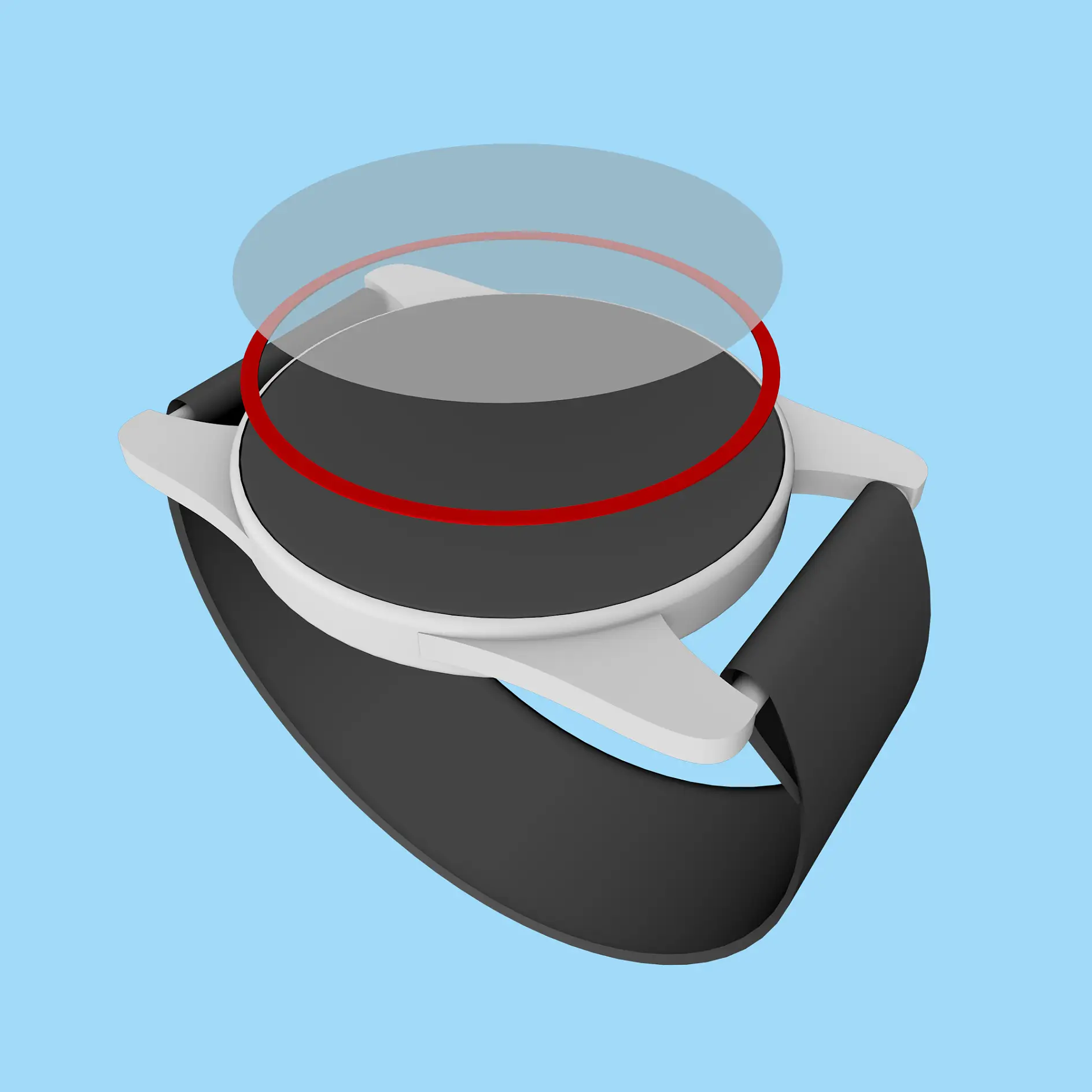

When it comes to areas of application, tesa’s main focus is in the smart watch segment on seamlessly attaching the front cover (lens mounting) and housing (back cover mounting). Another important role for our adhesive solutions is to securely affix the delicate sensors in fitness trackers that are used to monitor various bodily functions. “We focused on these two categories when tesa joined with global players from the electronics industry to tackle the development of innovative adhesive tapes, about three years ago,” says Dr. Robert Gereke, CEO of tesa. “This early and close cooperation has meant that we are now able to offer OEMs and suppliers special tapes that meet the specific requirements that apply to adhesive bonding of components in wearables.”

For wearable technology to gain widespread acceptance, the devices have to be both visually attractive and rugged enough to stand up to the elements – two key attributes our double sided tapes provide. As this futuristic category of personal electronic devices continues to evolve and grow, tesa will continue to support its unique needs.