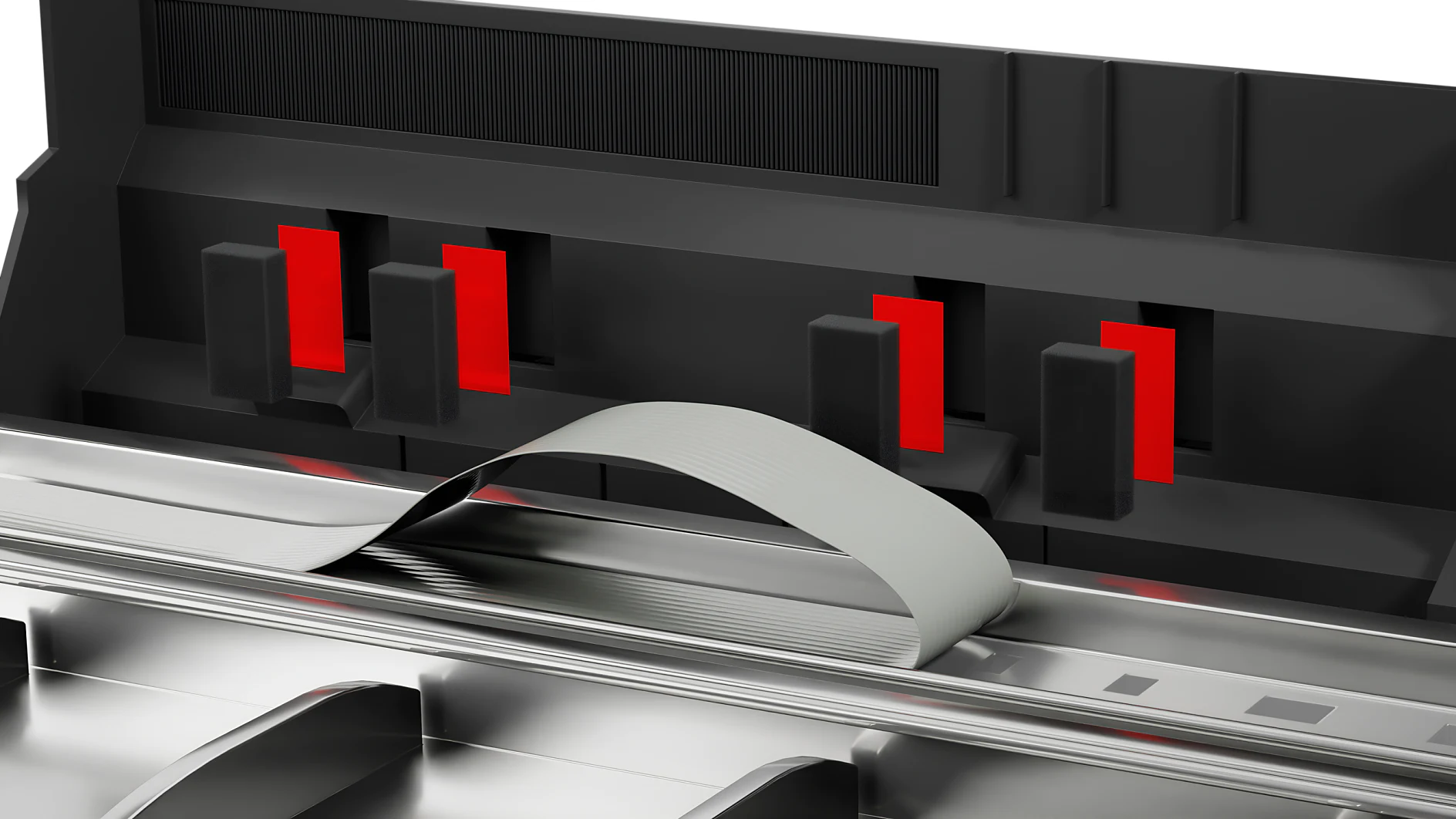

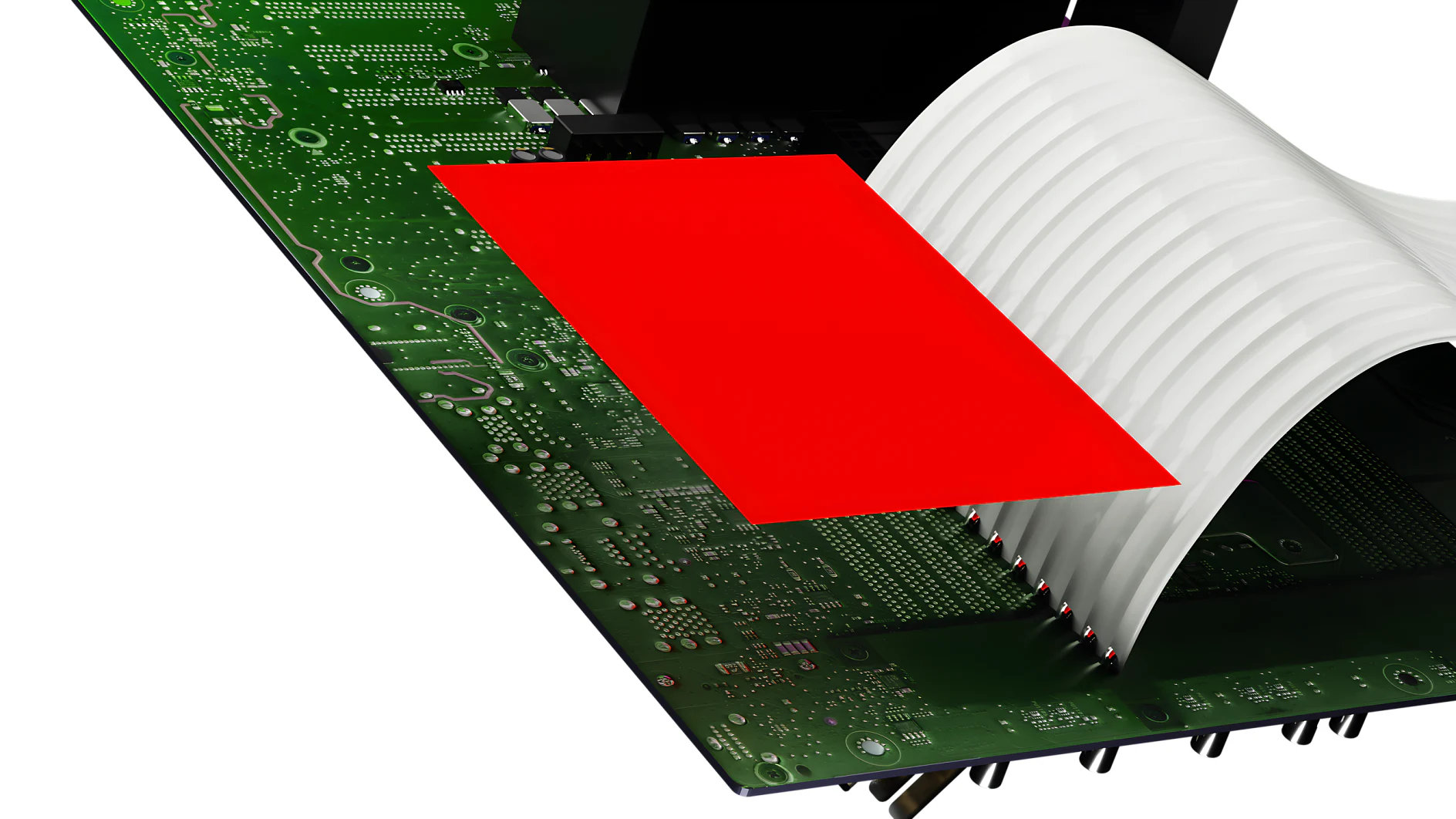

01Wire harnessing tapes

Within a copier or printer, cables need to be bundled neatly and insulated well to ensure reliability. When it comes to wire harnessing, our single-sided plastic and cloth tapes provide both flexibility and ensure good insulation. We offer tapes that have high tensile strength as well as a conformable backing that sticks to irregular surfaces.