Same reliable performance.

Same value.

It makes sense.

The future belongs to more sustainable solutions, but we understand that our customers expect our new products to perform at least as well as our conventional ones. That’s why we use as much recycled material for our more sustainable duct tapes as possible without compromising their reliability.

Famously easy to handle

We started the development of the new duct tapes by interviewing and sampling selected of our trade partners. We wanted to make sure that the tapes would meet the needs and expectations of the people who use them every day. Just like our conventional tapes, both the improved tesa® 4615 PCR and the new tesa® 60462 can be torn by hand. They unwind pleasantly, but not by gravity alone with ideal results in wrapping applications.

Successfully tested by our customers

In addition to our in-house results, we tested the new tesa® 60462 Heavy-duty Duct Tape by asking five customers to use it in a range of different and very demanding scenarios from road construction to the masking of wind turbine parts during sand blasting. They all told us that tesa® 60462 was up to the task. And they also approved of the fact that the new tapes contain more than 60 % PCR plastics in the backing and use a solvent-free adhesive. As the tape performed as expected, all five customers preferred the more sustainable product.

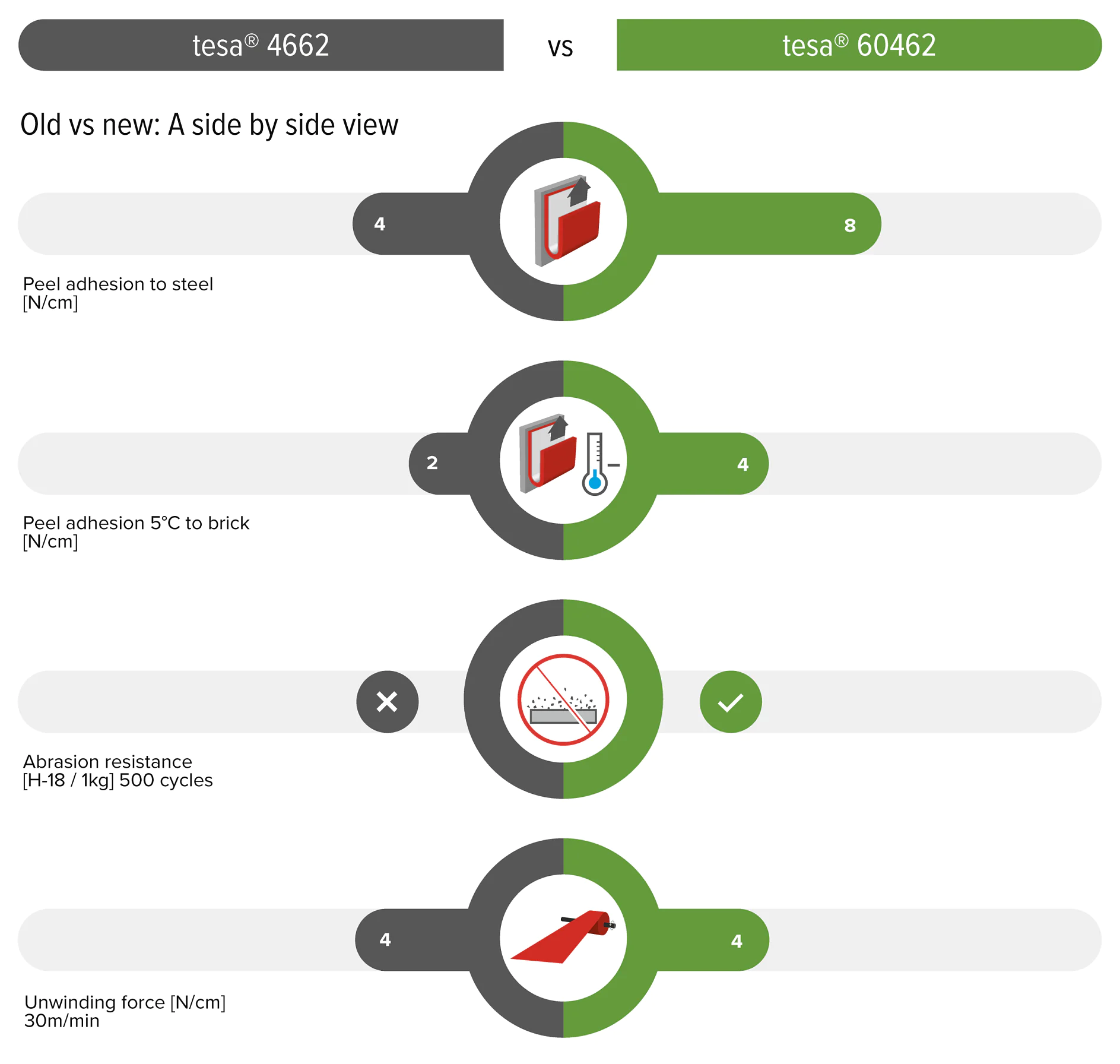

tesa® 60462: On par with previous products

The two most defining characteristics of the robust tapes, their peel adhesion on rough surfaces and their abrasion resistance, are on par with previous products. In our Customer Solutions Centers, we can test the peel adhesion at room temperature, but also at more extreme temperatures. Our new duct tapes were tested in our climate chamber at temperatures down to freezing. Here are the results: At 23 °C both new tapes offer stable performance, and at 5 °C the specially developed adhesive of tesa® 60462 still adheres securely to metals, plastics and also rough substrates such as bricks, proving that the tape works well in cold conditions.

Independent external certification

tesa® 4615 PCR: More sustainable, same performance.

With a performance as reliable as its predecessors, the improved tesa® 4615 PCR allows you the confidence to focus on your sustainability goals.

| tesa® 4615 PCR | tesa® 4615 conventional | |

|---|---|---|

| Robustness (thickness) | 0.18 mm | 0.18 mm |

| Peel adhesion (steel) | 7 N/cm | 7 N/cm |

| Peel adhesion (backing) | 5 N/cm | 5 N/cm |

| Unwinding force (30m/min) | 3.5 N/cm | 3.5 N/cm |

| Lowest application temperature | 5°C | 5°C |