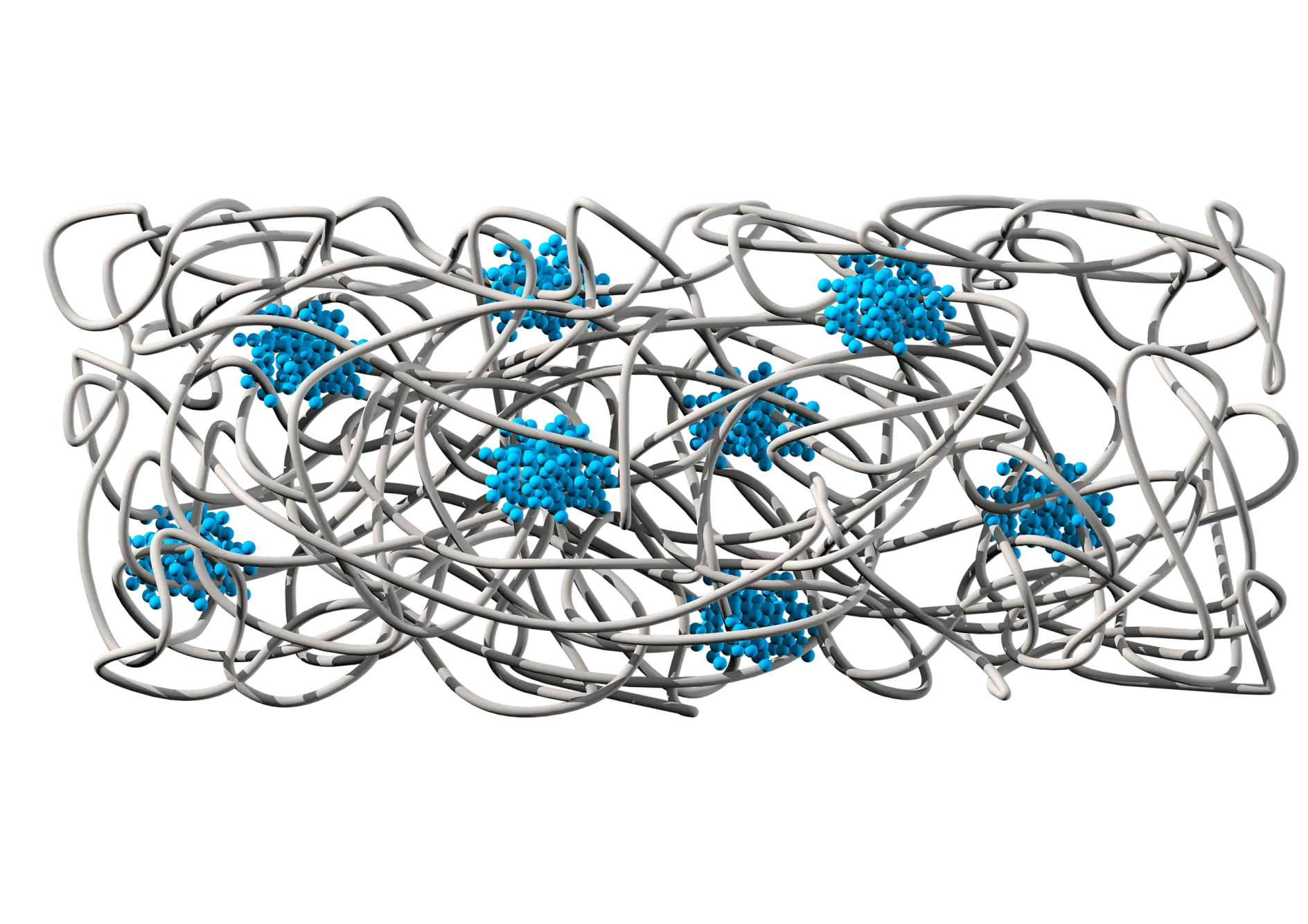

The secret to the success of synthetic rubber is in the structure of its chain of molecules: two hard ends on the outside (Styrene), a flexible, softer, rubbery middle part (Butadiene). So the structure is: Styrene – Butadiene – Styrene = SBS. That looks a little bit like a jump rope with extra long handles. The best part is: you can tailor this jump rope so that you can easily overcome any challenge with it.

Hard or Soft? Stay flexible

Technologies

Synthetic rubber has a unique molecular structure – perfectly suited for the development of adhesive tape. A brief portrait of the synthetic rubber properties and the answer to the question: What is synthetic rubber?

A "Jump Rope" for Every Occasion

The proportion of hard ends to the middle part determines how strong or firm the synthetic rubber is – and thus ultimately how mobile or soft the adhesive of adhesive tape is. The styrene-end segment determines the cohesiveness (internal strength) of the adhesive; the rubbery middle segment determines the adhesiveness. By itself, Synthetic Rubber does not harbor any adhesive properties. To create a pressure sensitive adhesive, tackifier resins need to be added. In contradiction to natural rubber polymers, the Synthetic Rubber polymer has a short length and a low molecular weight.

The flexible middle part of the molecule chain, also called an elastomer, is more stable with respect to aging than its natural counterpart. There has been synthetic rubber since the 1960s. We usually find it under synonyms such as SBC (styrene block copolymer), SBS (styrene butylene styrene), SIS (styrene isoprene styrene), SEBS (styrene ethylene butylene styrene) or hot melt (the latter is also available with a natural rubber and acrylate base).

Synthetic Rubber Properties

The special properties of synthetic rubber adhesives include their high tack. This means that adhesive tape with synthetic rubber adheres well on many surfaces – even on ones with low surface energy. Furthermore, it has outstanding shear resistance: it does not slip from the surface in the case of a lateral load.

The Advantages and Disadvantages

Adhesives with synthetic rubber share relatively low adhesion and cohesion at temperatures above approx. 40° C. Their resistance to aging is lower than other adhesive components, but better than with natural rubber. They are less suited for UV exposure, but that can be compensated by adding stabilizers.

The advantages clearly outweigh the disadvantages, however. To start with, the high tack, i.e. stickiness, is not inferior to the natural product in any way. Furthermore, the excellent peel adhesion is one of the most important properties of synthetic rubber: adhesive tape sticks well to difficult and normal, non-polar and polar surfaces.

The molecular "jump rope" constantly can be adjusted to the needs so that it is suited for numerous applications: from stiff and solid to soft and flexible. The well-known tesa Powerstrips®, for example, also contain synthetic rubber. And also coating transparent films is possible in contrast to natural rubber. Furthermore, synthetic rubber production allows for fast processes, which reduce production costs (for example in the case of sealing boxes).