Flexographic and process consumables

For label printing in Global Converter Markets

For label printing in Global Converter Markets

Our tesa® Softprint assortment is supported by our smart tape production process – leaving all foam cells within the tape backing intact for better cushioning and resilience over time. Selecting the correct foam hardness from our assortment will produce exceptional print quality by increasing your printing speed and overcoming print defects like banding, increased dot gain, and “pin holing.”

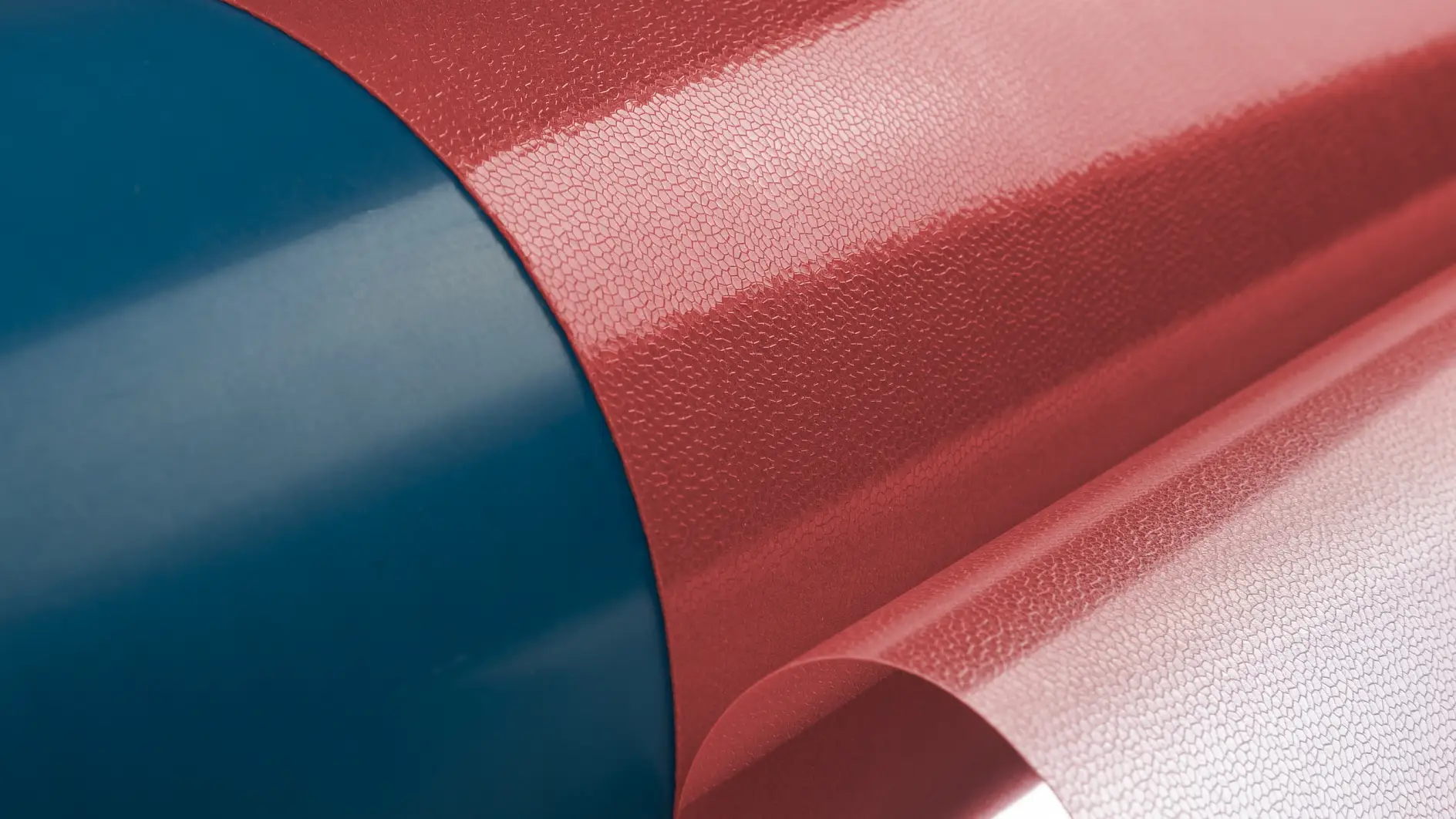

Our decades of experience as manufacturers of roller wrapping tapes have made our grip tapes a benchmark. They support a variety of manufacturing, converting, and printing processes that utilize roller systems and process materials such as films, textiles, paper, and more.

Ever striving for the highest quality and optimal solutions, the well-proven tape design has been improved even further over the years, ensuring maximum process reliability and efficiency.

The tape design allows for clean and accurate application, while at the same time ensuring easy removal. Applied on the roller, the tape will securely keep its position, even at elevated temperatures.

Head to the product page for more information:

tesa® 4863

Application step 4: Keep on wrapping the roller with the tape at even angles, leaving no gaps in between the layers.

Application step 1: Wrap the tape once around the roller at the desired angle and mark the point where the end of the roll meets the second turn of the tape.

Application step 2: Put the tape on a flat surface and cut it diagonally from the end of the roll to the marked point of the tape.

Application step 3: Remove the liner and start applying the tape, starting from the edge of the roller.

Surfaces to be bonded must be clean, dry, and free of dust, grease, oil, and release agents. For cleaning, only use clean cloths and material-compatible cleaning agents like tesa® 60040 Industry Cleaner. The components must be adapted to the ambient climate for a sufficient period to prevent the formation of condensation on the surfaces.

By cleaning the surfaces with a cleaning agent, you make sure all impurities are removed, such as:

Head to the product page for more information:

tesa® 60040

Adhesive mass residue may remain if an unsuitable adhesive tape is used or one has waited too long to remove the tape. In this case, tesa® 60042 Adhesive Remover can play a key role in the removal of such residues:

Head to the product page for more information:

For bonding – especially outdoors and on surfaces that are difficult to bond – we recommend the use of a bonding agent, like our tesa® Adhesion Promoters. Bonding agents form a layer on the surface to which the pressure-sensitive adhesive adheres particularly well.

Indeed, there are plastics and other materials to which adhesive does not stick well. Polyethylene (PE), polypropylene (PP), Teflon, rubber, and silicone to name a few. Experts call this "very low surface energy."

The exciting thing about a primer is it increases this surface tension, which lets the tape stick to the substrate more strongly. This layer also prevents water from entering the adhesive joint and thus enables consistent outdoor bonding.

By partnering with tesa as a Converter Partner, you have decided to join our network of strategic business allies. Your company is recognized as a strong and proficient resource and working together we believe we can mutually grow our businesses.

As a Converter Partner, your company has access to the consistent high quality of the extended tesa® assortment as well as to the expertise and support of our sales, supply chain, marketing, customer support, and Customer Solution Center teams.