Proven and reliable: our flame retardant and halogen-free tape solutions

Get to know our product assortment: our flame retardant and halogen-free tape solutions

To ensure health and asset protection, fire safety regulations are of special importance in a variety of industries, such as aviation, trains, marine, building and construction, elevators, automotive and e-mobility.

Our tesa® flame retardant assortment complies with fire regulation standards and all tapes are halogen-free, which supports smoke reduction and less gas toxicity. The wide variety of the assortment extends from thin double-sided tapes for lamination demands to the PE- and acrylic foam products for the constructive solutions.

Advantages of our flame retardant tapes:

- Compliance and fulfillment acc. to industry standards UL94 and FMVSS 302

- All products are halogen-free

- High performance on a variety of surfaces

- Reliable long-term bonding

- Large assortment for a wide range of applications

Let us show you briefly tesa® flameXtinct

tesa® flame retardant product family

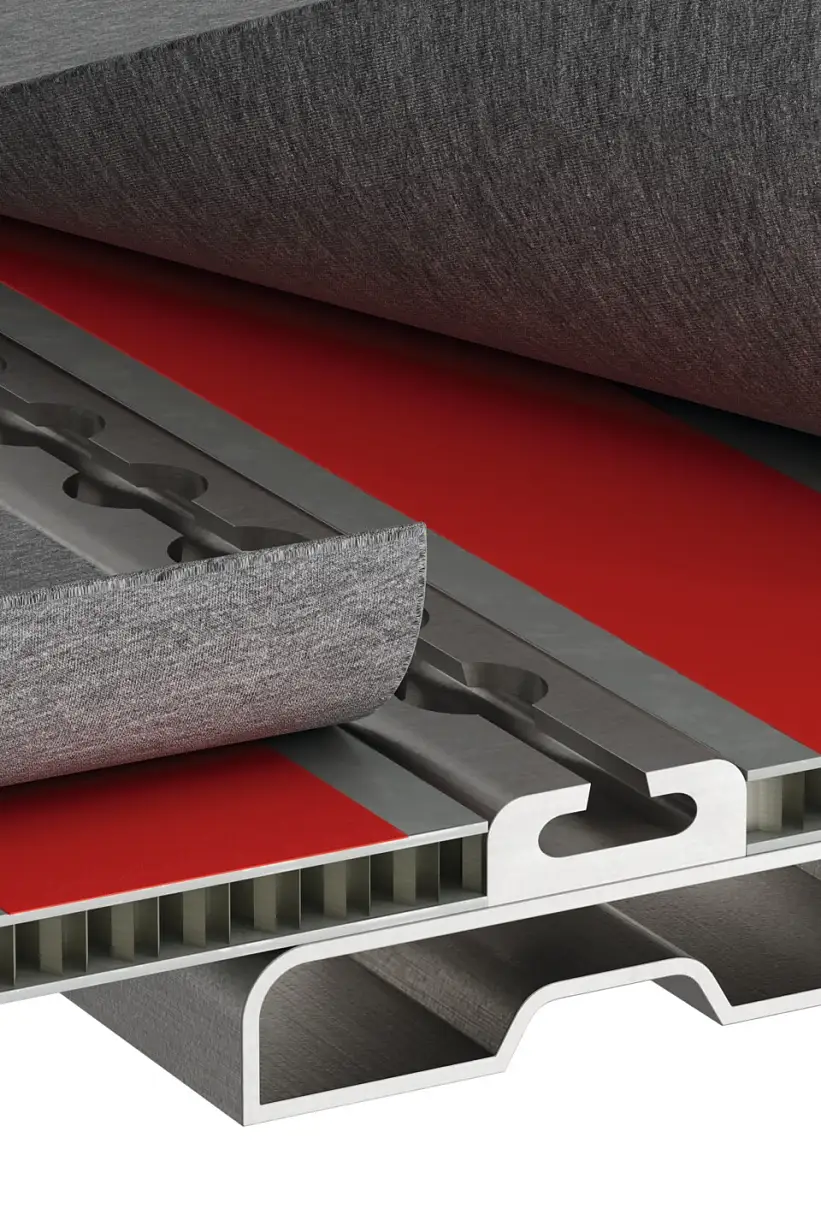

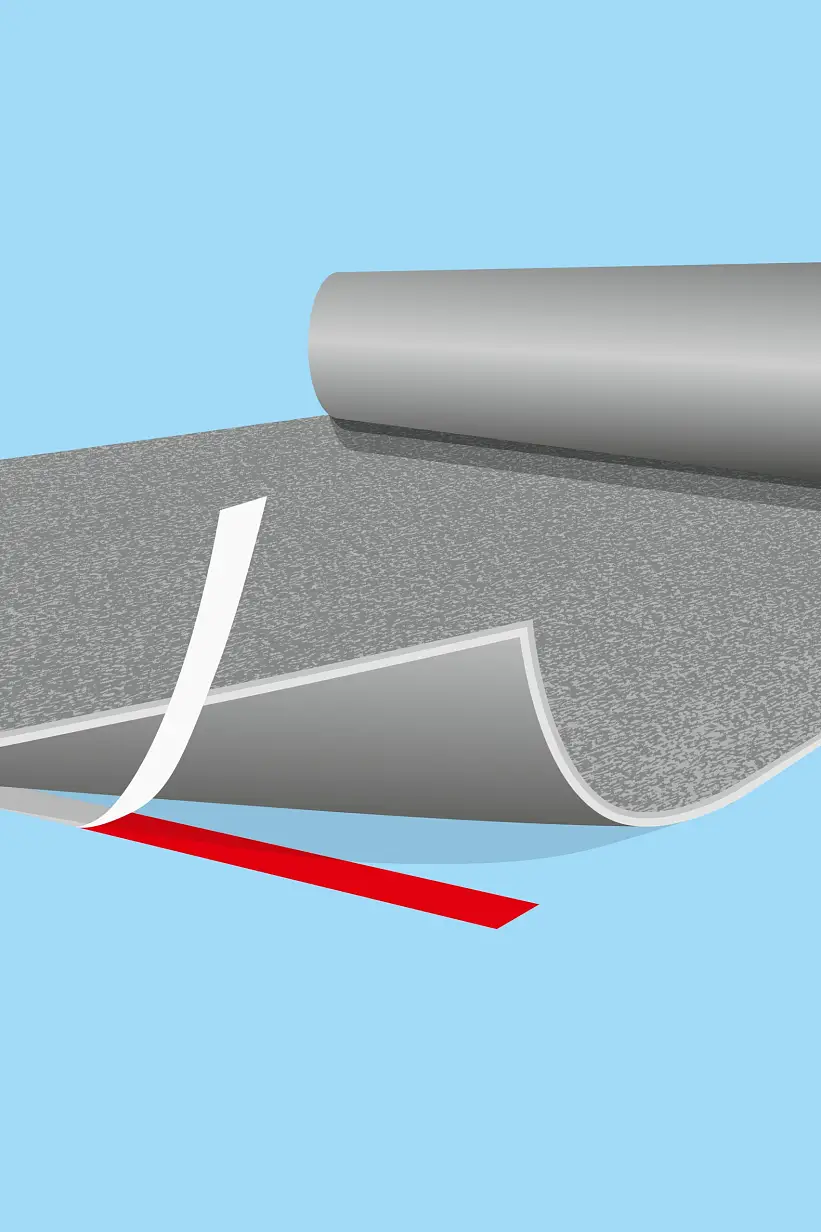

New tesa® flameXtinct 45020: Secure carpet mounting in the transportation industries

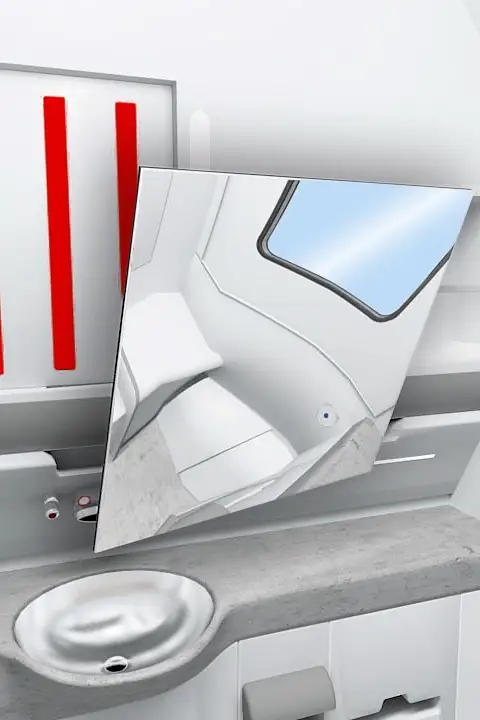

tesa® flameXtinct 45020 is used in trains, buses and airplanes and wherever increased fire protection requirements apply, because every second can make the difference in an emergency.

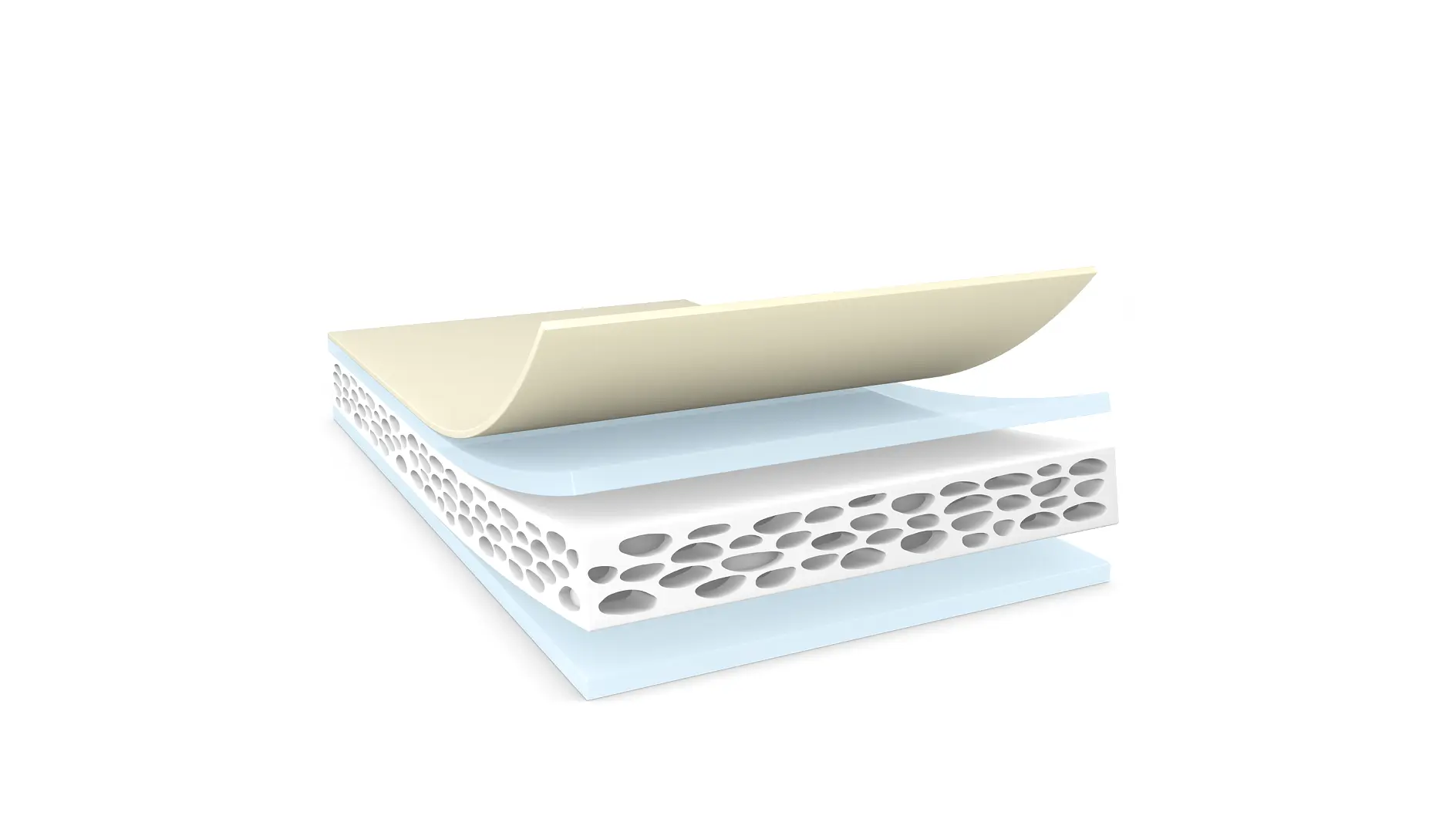

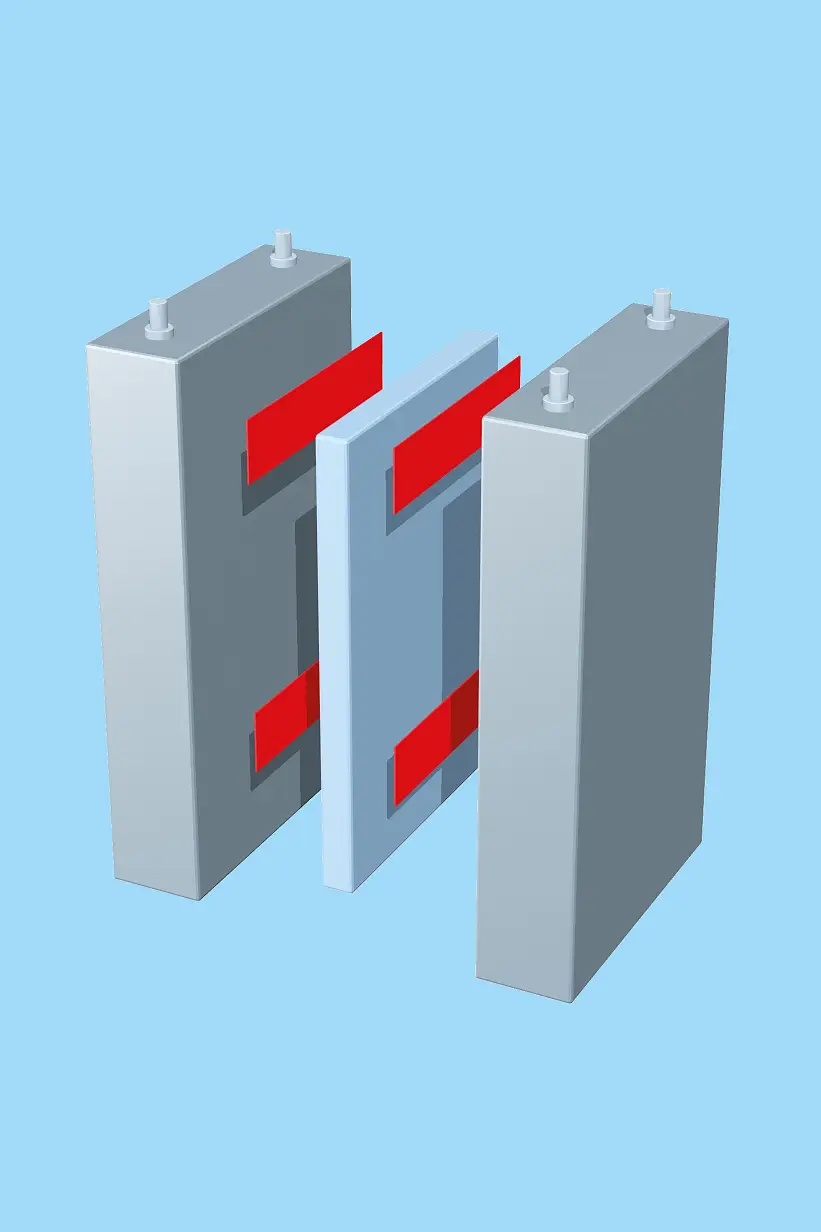

PE foam backing - tesa® flameXtinct 45001

tesa® flameXtinct 45001 product is a flame retardant PE-foam tape for permanent mounting in demanding applications. The tape comprises of a flame retardant acrylic adhesive and flame retardant PE-foam with excellent bonding strength.

Product advantages:

- Proven flame retardant characteristics according to UL94 (HBF-HF1)

- Halogen-free (conformable acc. REACH and ROHS)

- Excellent adhesion characteristics on a variety of surfaces

- High conformability and shock absorbing

- Extremely light weight compared to alternative flame retardant bonding opportunities

Main applications:

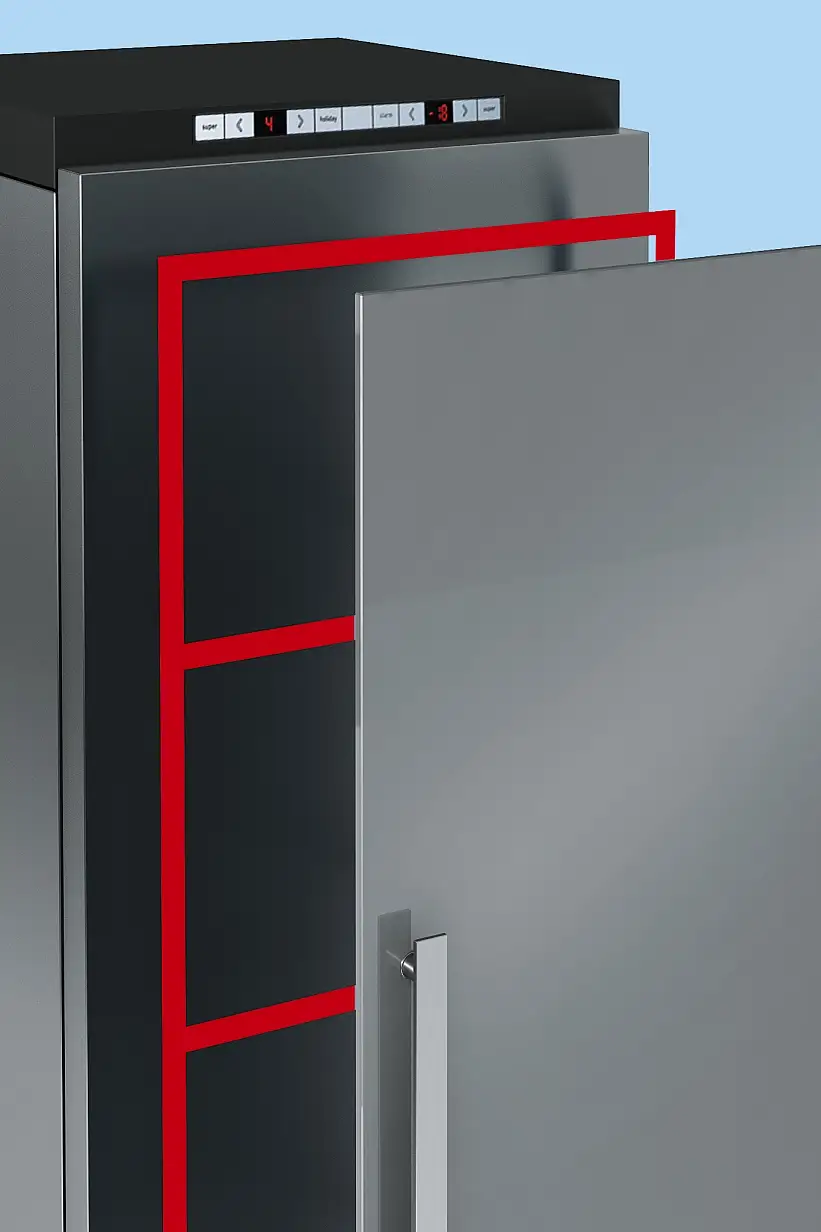

- Stiffener bar mounting e.g. in elevator walls and landing doors (building industry)

- Fastening of lightweight components (e.g. marine and special vehicles)

- Bonding in the passenger area of trains

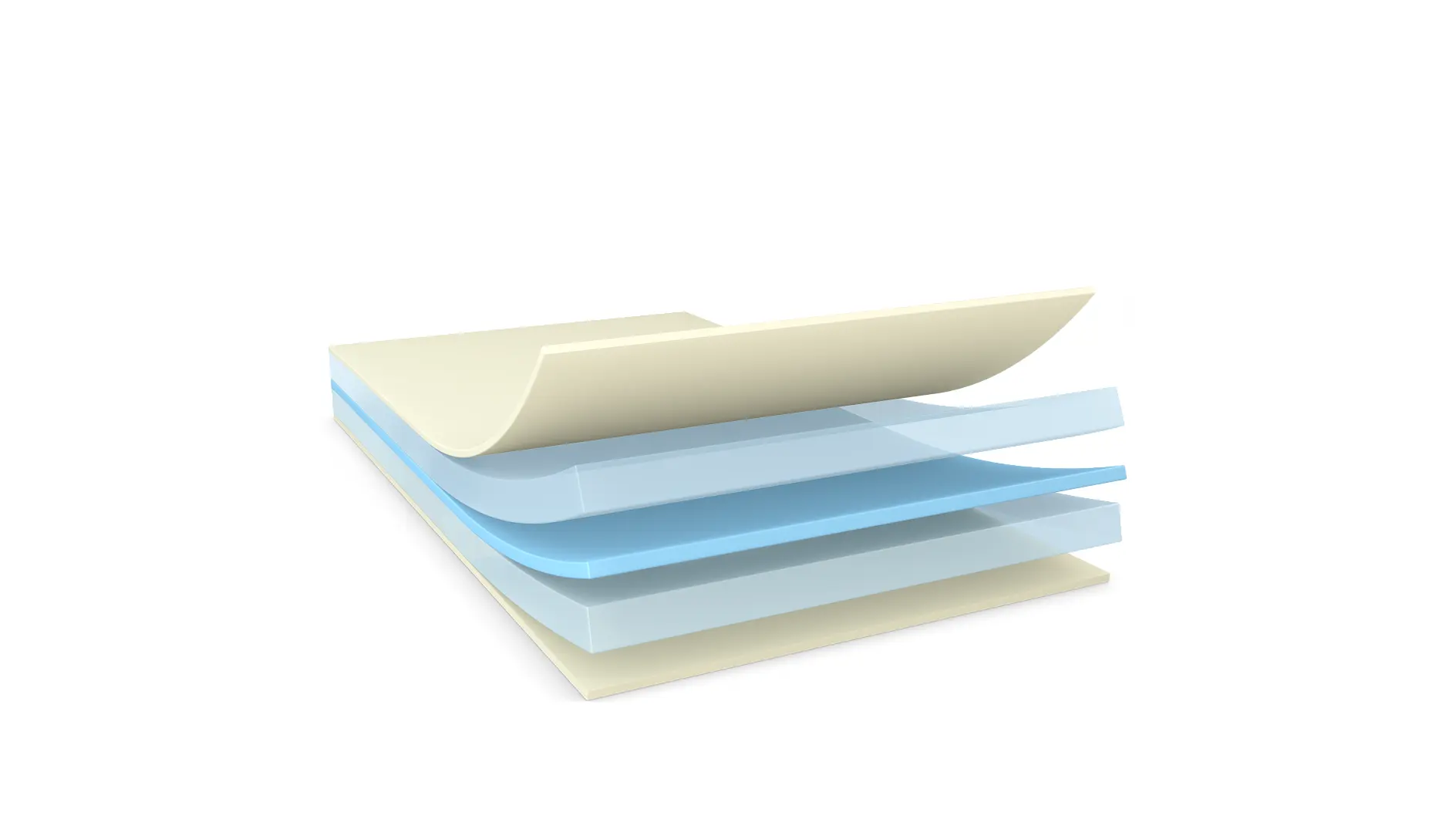

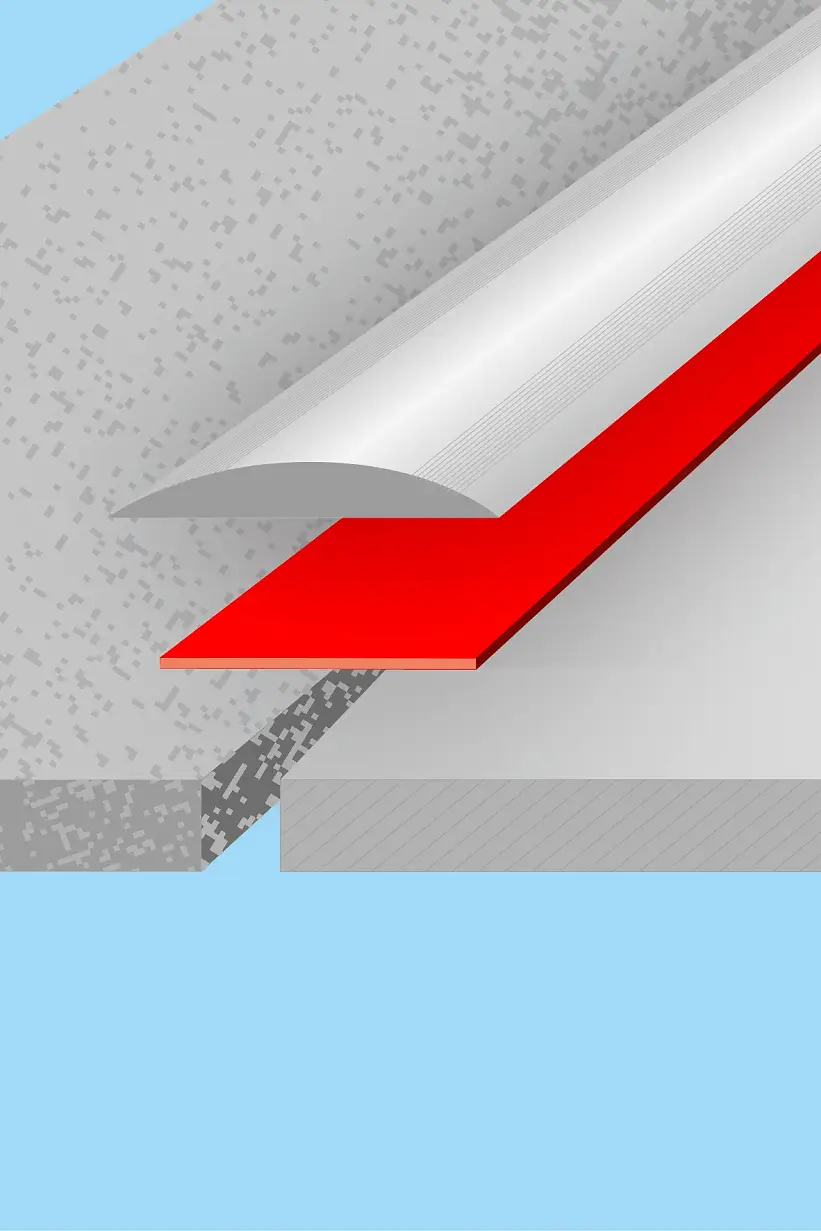

Filmic and non-woven backing

The thin double-sided flame retardant adhesive tapes are available with product thicknesses from 50 μm to 200 μm. Flexible PET and non-woven backing makes them suitable for laminating applications with flame retardant requirements. The high-performance acrylic adhesive makes the products optimal for a variety of applications with low carrier thicknesses.

Product advantages:

- Tested acc. to UL94 and FMVSS 302

- Halogen-free products

- High initial performance and bonding strength on polar substrate

- Excellent die-cutting properties in the converting process

- Transparent and translucent backing for invisible bonding

Main applications:

- Various mounting applications in the EV battery system (e-mobility market)

- General mounting, lamination and converting application with flame retardant properties

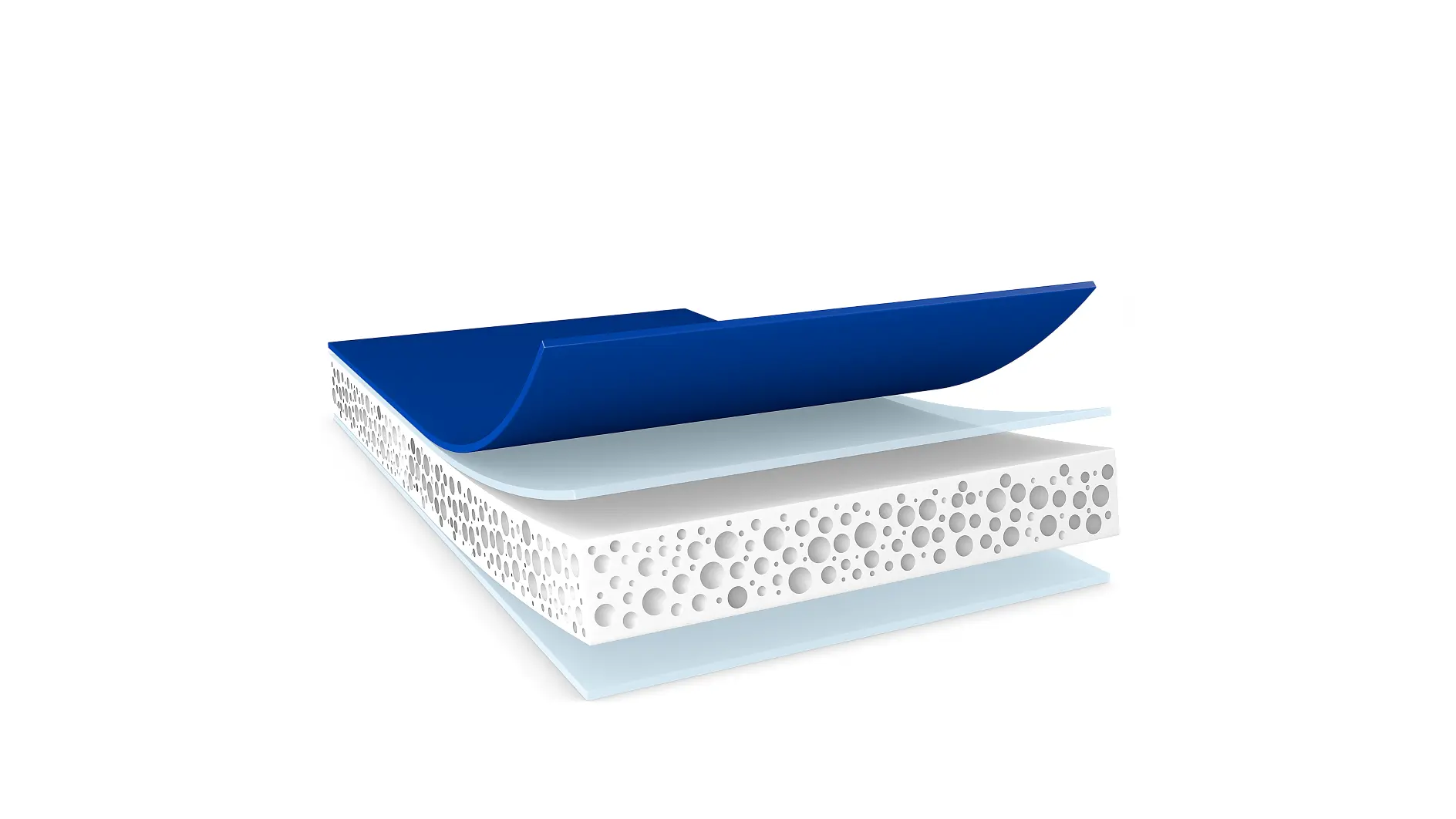

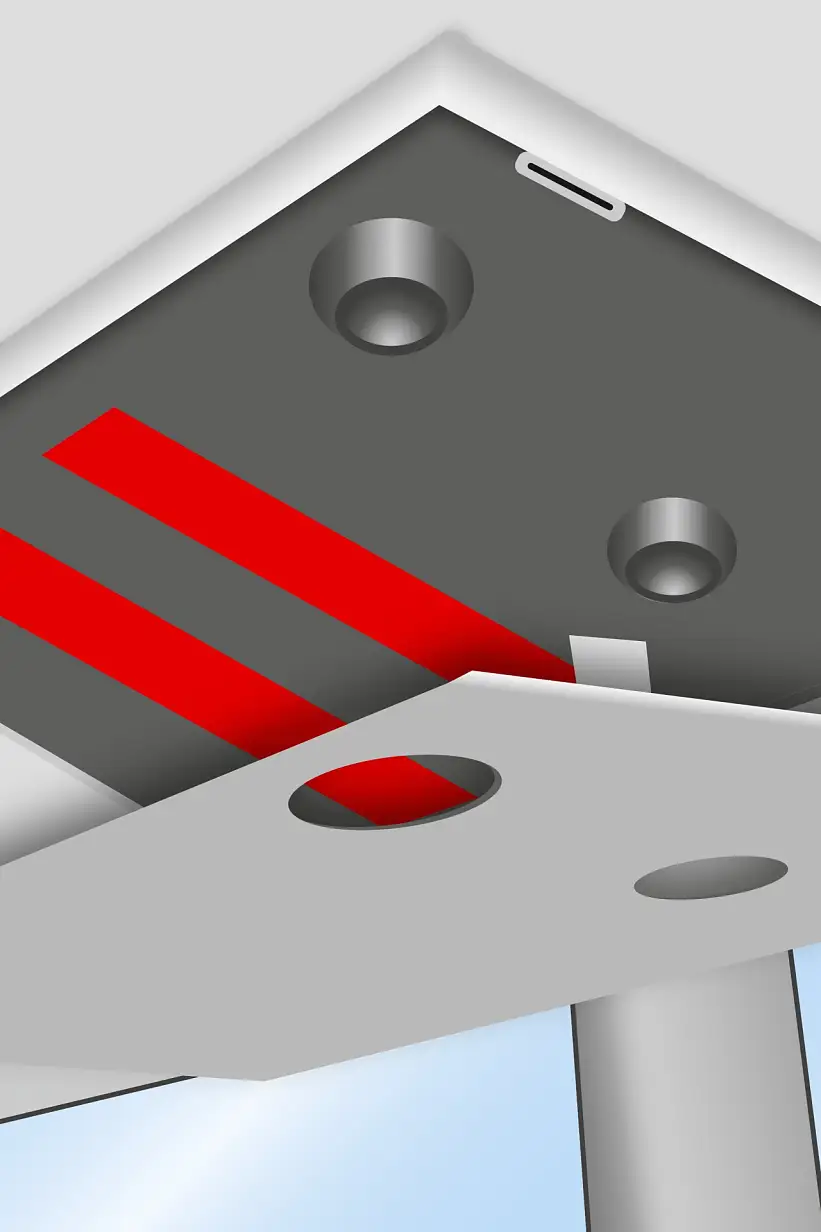

Acrylic core backing - tesa® flameXtinct 45063 and tesa® flameXtinct 45065

tesa® flameXtinct 45063 ynd tesa® flameXtinct 45065 are flame retardant acrylic core tapes for permanent bonding applications. The acrylic core allows for the compensation of thermal elongation and good adhesion to various substrates such as: metals, powder coated surfaces, glass and plastics.

Product advantages:

- Proven flame retardant characteristics according to UL94 and FMVSS 302

- Premium acrylic core for high demanding applications

- Viscoelastic product properties

- High performance adhesive

- Halogen-free

Main applications:

- Stiffener bar mounting e.g. in elevator walls and landing doors (building industry)

- Bonding of decoration profiles and kick plates e.g. appliance industry

- Long-term bonding of decorative and constructive elements for e.g. train, marine or special vehicle applications

Quick and easy: our flame retardant assortment at a glance

| tesa® flameXtinct 45051 | tesa® flameXtinct 45020 | tesa® flameXtinct 45001 | tesa® flameXtinct 45063/45065 | tesa® FR58375 | tesa® FR58372 / 58373 | |

|---|---|---|---|---|---|---|

| Product design | Acrylic adhesive PET backing | Acrylic adhesive PET backing | Acrylic adhesive PE-foam backing | Acrylic adhesive Acrylic core | Acrylic adhesive Non-Woven | Acrylic adhesive PET backing |

| Tape thickmess | 200 µm | 190 µm | 1000 µm | 800 µm / 1200µm | 130 µm | 50µm / 80µm |

| Color | Transparent tape Red liner | Translucent PET White Liner | White tape Red liner | White tape White liner | White tape White liner | Transparent tape White liner |

| UL 94 | VTM-0 | Not tested | HBF HF-1 | V-2 | VTM-0 | VTM-0 |

| FAR 25.853 | ✔ | ✔ | ✔ | ✔ | Not tested | Not tested |

| Gap filling | − | − | ✔ | ✔ | − | − |

| Shock absorption | − | − | ✔ | ✔ | − | − |

| Light-weight | ✔ | ✔ | ✔ | − | ✔ | ✔ |

| Viscoelasticity | − | − | − | ✔ | − | − |

| Conformability | ★ | ★ | ★★★ | ★★ | ★★ | ★ |

| Standard bonding | ★★★ | ★★★ | ★★★ | ★★★ | ★★★ | ★★★ |

| Demanding bonding | ★ | ★ | ★★ | ★★★ | ★ | ★ |

| Temperature resistance | ★★★ | ★★★ | ★★ | ★★★ | ★★★ | ★★★ |

Testing and certification process of tesa® solutions

Comprehensive R&D and laboratory support

Our Customer Solution Center provide exclusive testing by analyzing of industry standard materials in combination with our adhesive tape solutions solutions. Customized tests for special materials are also possible in order to certify individual combinations. We test, for example, the adhesive performance, flammability (based on UL 94) and climate cycle tests. In some cases, these go beyond what the respective standards require of our products and are the basis for the extraordinarily high quality of our adhesive tape solutions.