In consumer and industrial packaging applications, paper is often used as the main component.

Walki’s speciality is adding barriers to the paper to protect the goods inside the package. For an appealing packaging appearance, Walki also has a long tradition in flexographic printing and operates over 10 flexo printing presses providing superior print quality.

Most recently, Walki has invested in a new high-speed, 10-color flexographic printing machine in its Jatne plant in Poland.

Remarkable sustainability targets and plate mounting efficiency at Walki

Markets

At Walki in Jatne (Poland), ambitious sustainability targets and the use of tesa® Twinlock go hand in hand

Leading producer of multi-layer laminates and protective packaging materials

Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials.

To best cater to customers worldwide, Walki continuously invests in state-of-the-art production facilities and drives the tradition of innovation and exceptional service.

At Walki, we believe in a sustainable and circular tomorrow. We want to be the recognized leader in sustainable packaging and engineered material solutions. That is a vision we work towards relentlessly every day, together with our customers.

Copyright © Walki Group

Speaking of flexo printing, that is where tesa® Twinlock, our self-adhesive flexo sleeve, came into play.

At first one set of sleeves was bought, and after one year of testing, 100 sleeves followed.

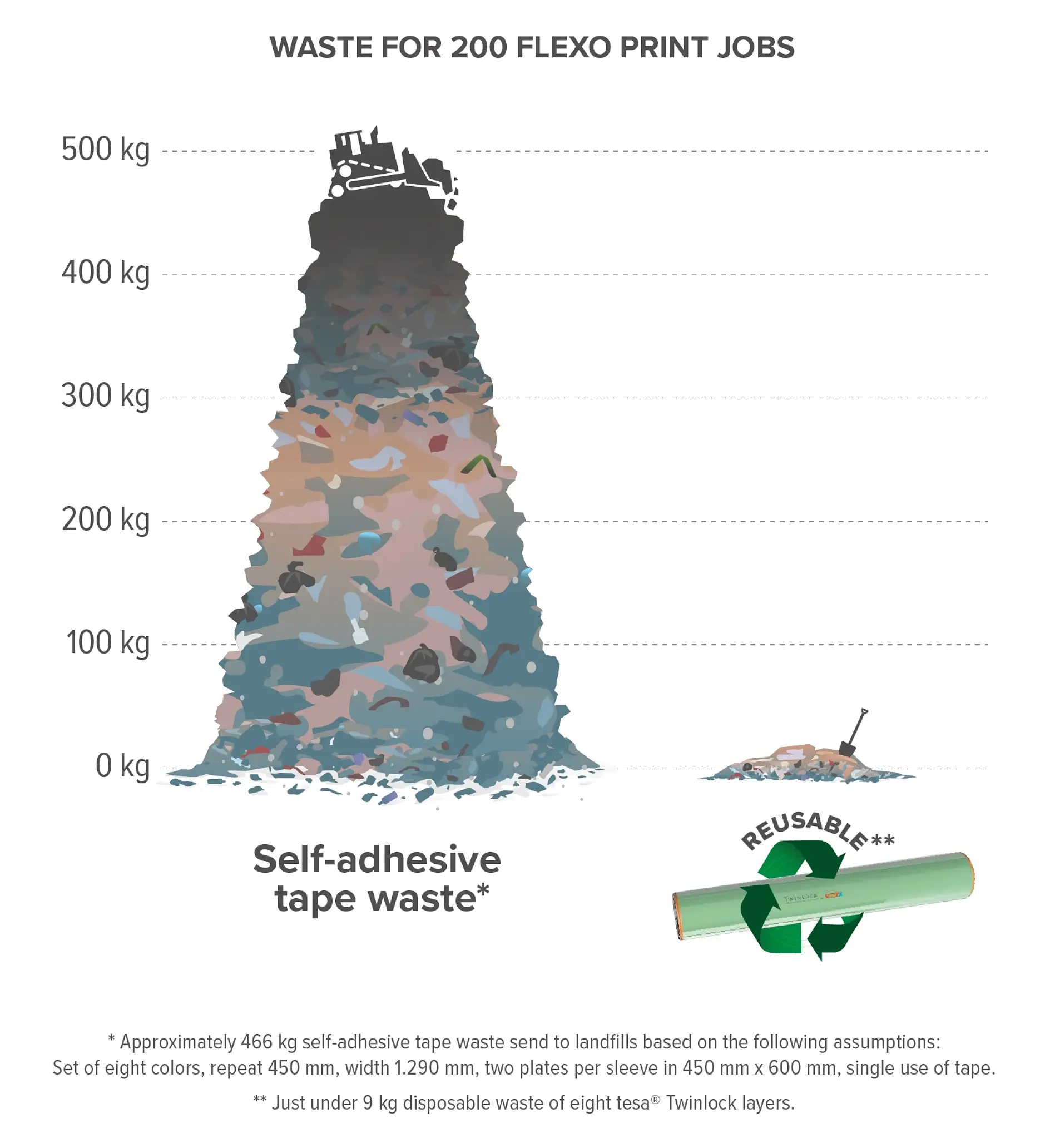

The main drivers to check out tesa® Twinlock were the reduction of plate mounting tape and the corresponding waste prevention, as well as the idea of improving the efficiency of the mounting process.

Read the full story of tesa® Twinlock @ Walki in our interview:

WHAT MADE YOU DECIDE TO START USING tesa® Twinlock?

"As the orders are becoming shorter every year we had to find a mounting technology that will allow us keeping the right efficiency on the printing presses. Printing plates mounting and demounting with tesa® Twinlock is 50 % shorter than traditional tape mounting / demounting as there is no tape in the process. The tesa® Twinlock technology with its effectiveness allows us to be more flexible with our production plan. Today we can react much faster on changing needs of our customers.

tesa® Twinlock sleeves ensure very good plate adhesion during printing, even at high print speeds. In the beginning we were afraid of possible damages to the sleeves, but we saw that by following some simple rules we can avoid it. We don’t have to treat the sleeves in a very special way."

WHICH CUSTOMER REQUIREMENTS REGARDING SUSTAINABLE PACKAGING DO YOU FULFILL?

"When it comes to sustainability, there are three main types of solutions Walki is working with: products that are easy to recycle, compostable and/or biodegradable products, as well as products that are based on renewable resources and thus lowering the CO2 footprint. The right solution or combination of solutions is decided based on customers and end-customers needs. At the same time one needs to have sufficient barrier properties to protect the goods inside the packaging. Many customers are also interested in sustainable printing processes, for example using water-based inks instead of solvents."

Copyright © Walki Group

WHAT ARE YOUR ACTIVITIES REGARDING SUSTAINABILITY?

"At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. In addition to developing sustainable solutions for our customers, Walki has initiated an internal continuous improvement program concentrating on reducing waste from its operations and improving production efficiency – more with less. We are also, for example, using environmental friendly water-based inks in all our printing operations and invested in new state of the art printing technology."

HOW IMPORTANT IS IT TO REDUCE WASTE DURING THE PACKAGING PRINTING PROCESS?

"This is becoming more and more important as the average order sizes are getting smaller and the number of change-overs is increasing. Without modern printing machines, optimised processes, and innovative solutions - like tesa® Twinlock - this would lead to increased waste volumes and unfavourable developments when it comes to sustainability."

WHICH BENEFITS DID YOU ACHIEVE WITH THE IMPLEMENTATION OF tesa® Twinlock?

"With tesa® Twinlock we have exchanged the standard sleeves and tapes, and the cost has returned within 1 year from the purchase. Thanks to reducing the time of mounting process to 50 % we can keep printing press efficiency on a very good level. tesa® Twinlock sleeves work very well on high speeds. We don’t have problems any more with printing plate edge lifting during the printing process."