Adhesives for the metal industry: strength every step

of the way

The metalworking industry is at the core of everything that moves the modern world. From small household items to cars and whole railway networks. Without metal manufacturing, life as we know it would come to a standstill. To keep the competitive construction and manufacturing market running smoothly and without quality-related hiccups, we offer adhesive-tape solutions for this diverse market.

Suitable for the entire metal industry product lifecycle, from basic steel to superior products and everything in between, our tapes are a reliable partner in all segments. Optimize your proven processes with our versatile and long-lasting adhesive portfolio for metal-to-metal bonding and other material combinations.

Metal manufacturing and metalworking: the 5 main applications

The metal-manufacturing and metalworking industry covers almost all steps of the metal-manufacturing process. Before metalworking companies can start creating the finished product, the prematerial has a manufacturing journey of its own: from core starting to metal surface protection and the finished material.

Metal adhesive tapes are a key factor in this journey, as a high-quality end product requires effective bonding in a variety of application scenarios specific to the metal industry. But the bonding capabilities do not stop there. With adhesives for attaching metal to plastic or metal to concrete, our range of tapes is as diverse as your industrial challenges.

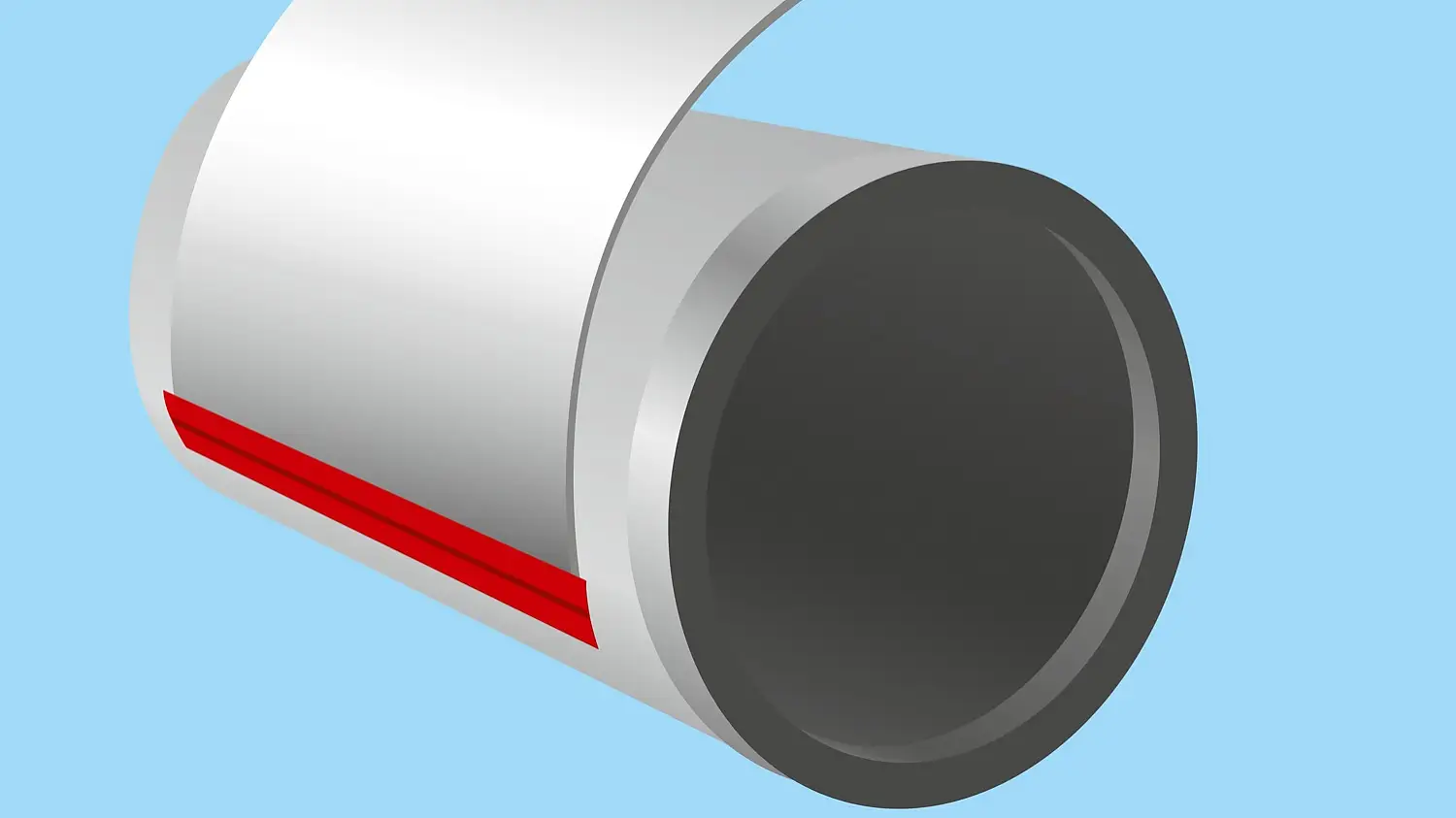

1. Metal coil core starting: the starting point

With our wide range of tesa® products suitable for core starting, your metal coil receives the perfect foundation. Robust products need especially strong cores, making a resilient core the heart of any metal coil. Our adhesive tapes ensure a secure first connection between product and core during the rolling process. Our tesa single- and double-sided tapes made with PVC, PET, PP, or cloth backing for reliable strength are suitable for the different thicknesses and retention forces of individual steel grades.

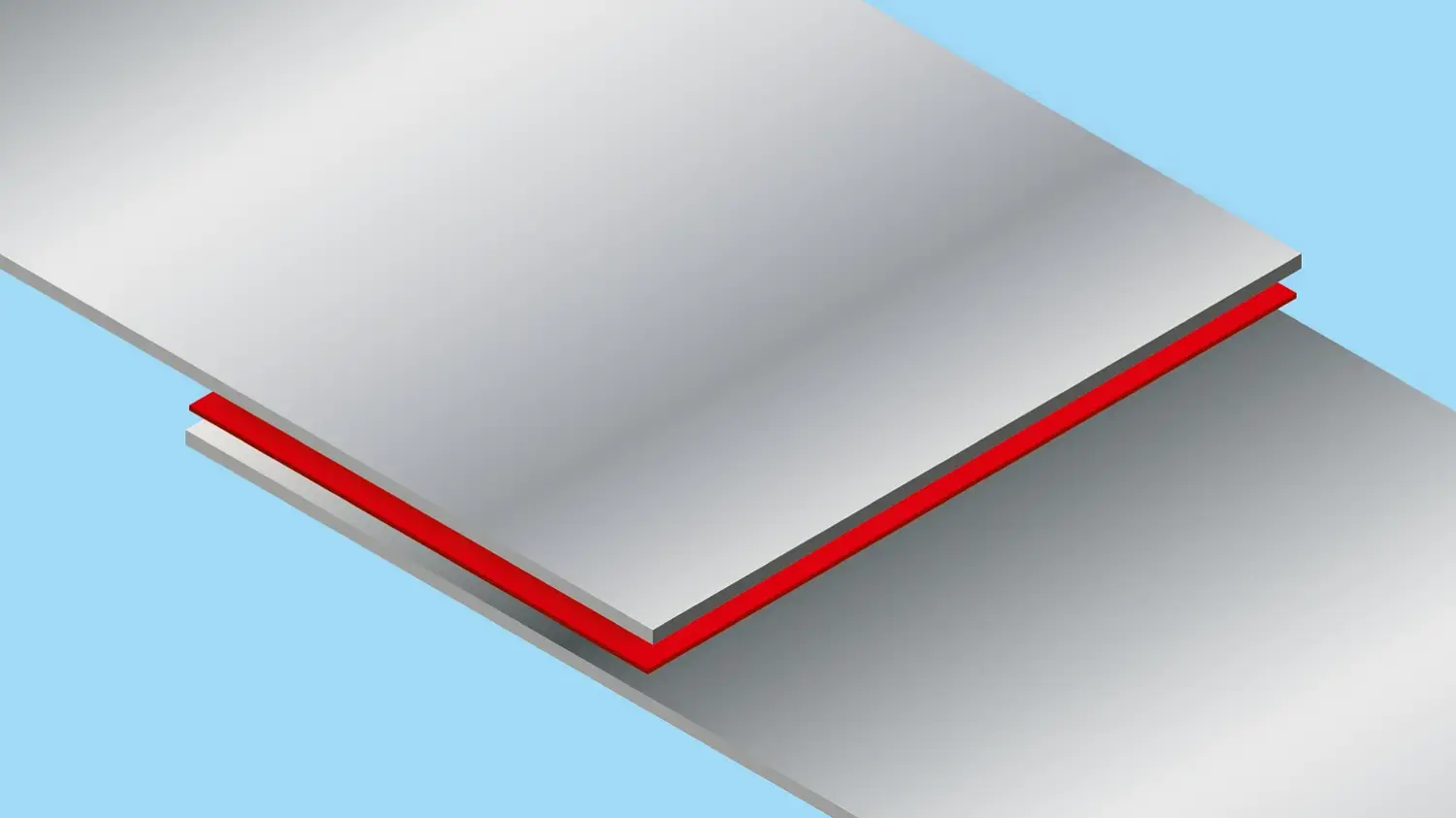

2. Metal overlap/butt splicing: optimized production

High stress resistance and high adhesion of our proven adhesive tape system enable efficient overlap splicing processes. Our metal tape provides excellent initial tack for immediate bonding, even to heavy-duty materials.

If you want to avoid overlaps in metal splicing to optimize material use, butt splicing with our single-sided tapes is the answer. Our self-adhesive tapes with customized adhesive systems reduce metal material waste compared with overlap splicing for a clear cost advantage and economic handling.

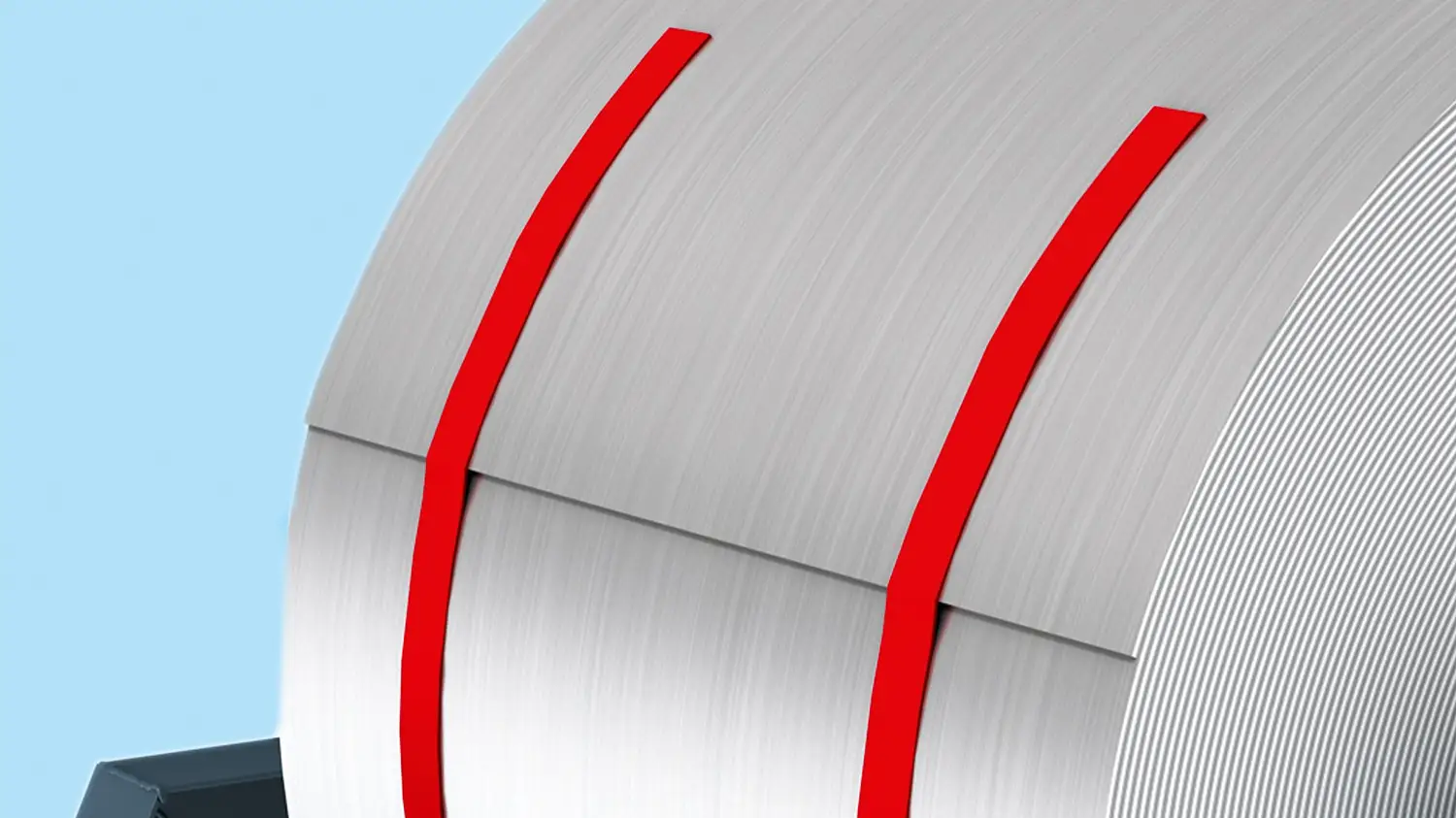

3. Metal coil end tabbing: transport safety

Our tesa® adhesive tapes offer a secure bond to various metal and steel surfaces. When a metal coil is prepared for transport, a high level of safety for handlers is key. End-tabbing tapes are at the forefront of this effort. Designed to prevent tearing and with shear-resistant adhesives, the high tensile strength of these specialty tapes prevents lift-up during transport so that the material stays in its designated space. Natural and synthetic rubber tapes are the basis for this desired strength and versatility. Their combination of high adhesion value to steel and clean removal gives you peace of mind during transport logistics without compromising the appearance and quality of the delivered product.

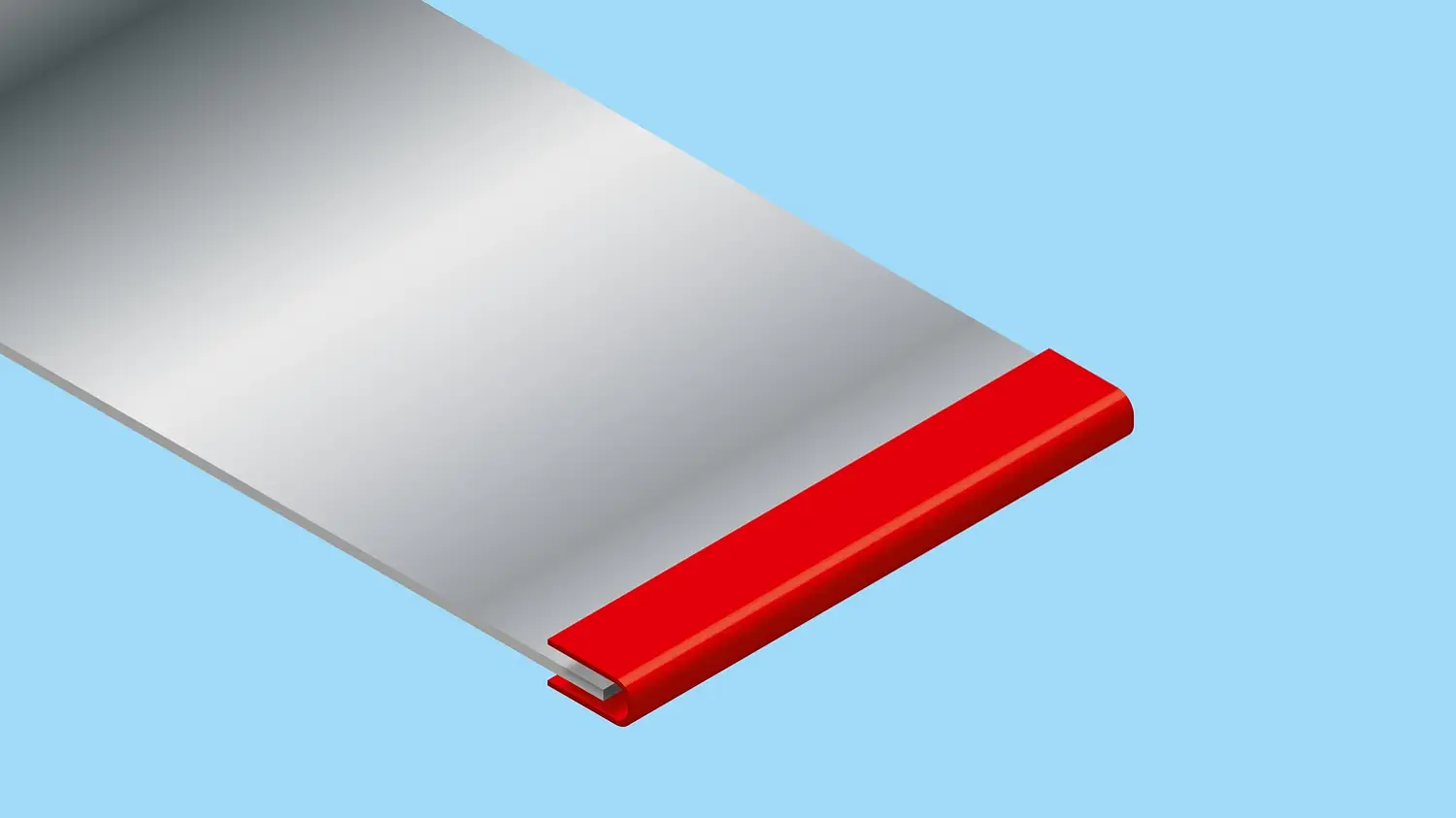

4. Metal edge and surface protection: not a scratch

Further down the metal-working value chain, different specialization processes await aluminum and steel products. Edge and surface protection are important factors for personnel safety to prevent injuries and protect the semi-finished and finished products from damage. Scratches, dust, and dirt can compromise the metal’s quality, so tapes with high tack and a short dwell time ensure fast application before internal or external transport. This protects handlers, saves valuable resources, such as time, and is a prerequisite for the next step of the product’s journey.

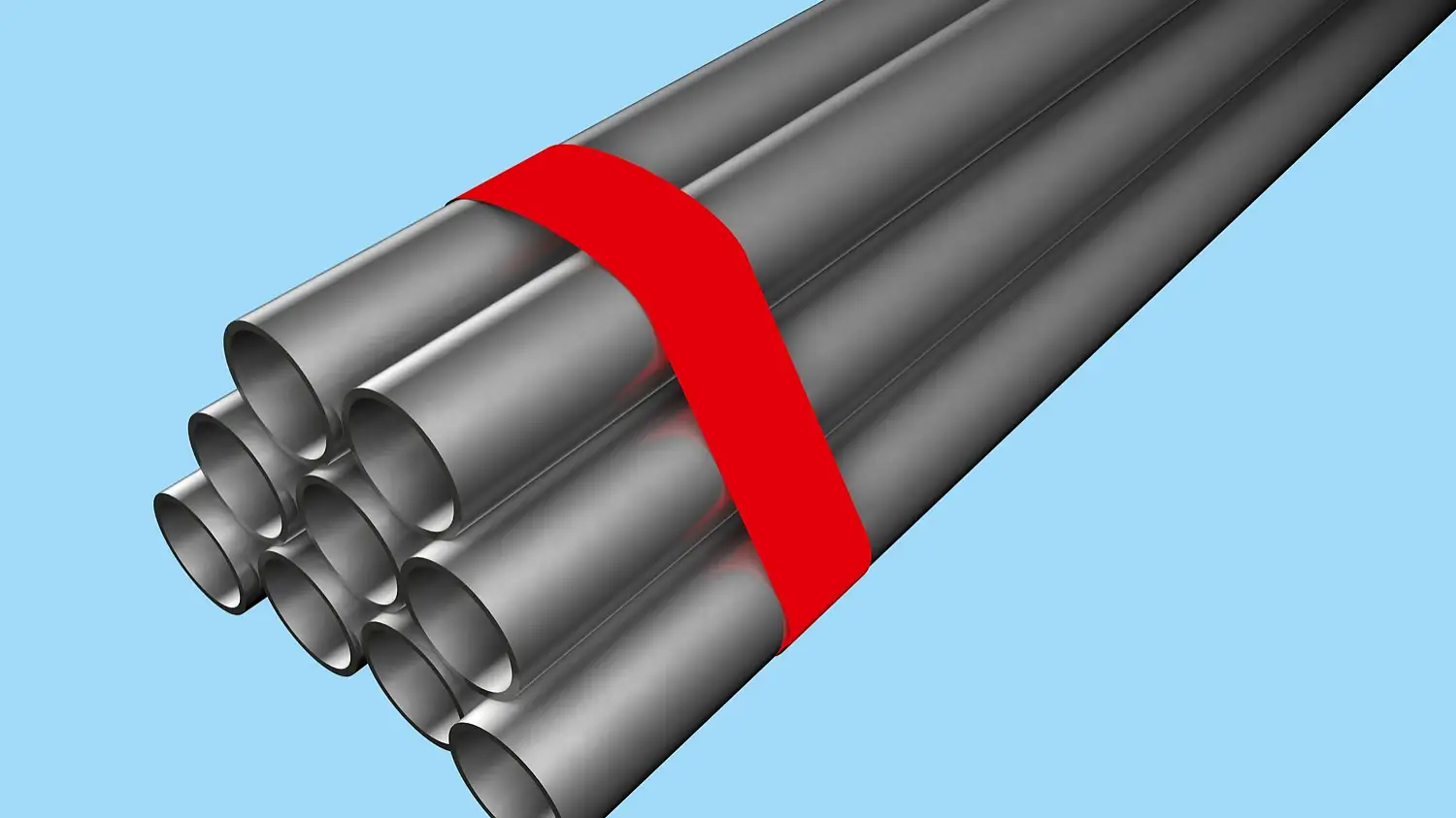

5. Metal bundling and metal marking: all sorted

When the forming and finishing processes are completed, products are ready for logistics and transport. For the safekeeping of staff and products, our strong single-sided tapes, such as our heavy-duty duct tapes, are ideal for metal bundling and marking of any type, including color-coding. We have even found ways to make our duct tape more sustainable, for example tesa® 60462 is made with 60% recycled material in the backing and our well-known solvent-free synthetic rubber adhesive. This tape is not only stronger but also more sustainable than ever before. Tearable manually, they are practical on-the-go support when you require additional security. Different grades, sizes, and more factors can be identified easily, and thanks to specific adhesive characteristics, they are even suitable for painted metal. With our tape portfolio, you can rest assured that products arrive at their destination in bundled units with clear identification for quick distribution and handling.

Our range of adhesive tape arount metal

Explore our cutting-edge adhesive solutions tailored for the metal industry. Our advanced adhesive tapes are designed to meet the high standards of metal fabrication, offering secure and durable bonding for various applications. Engineered for efficiency and reliability, our adhesive tapes enhance both performance and productivity. Browse our product range to find the ideal adhesive solution for your metal industry requirements.

Didn't find what you were looking for?

Contact our industry experts

Contact us and discover how we can help you with your material-specific bonding challenges.