Dobbeltsidede bånd

udviklet til dine

produktionsbehov

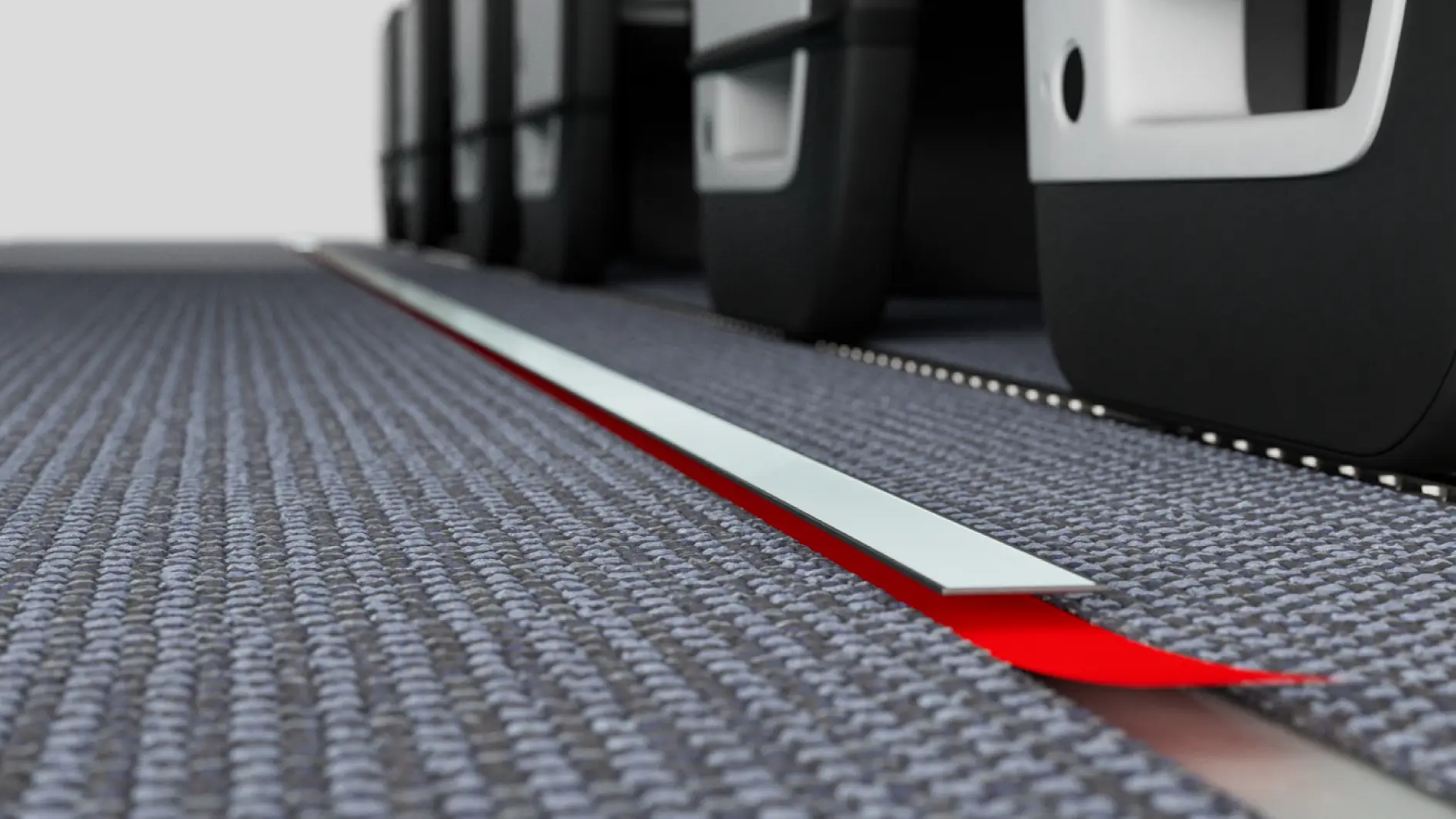

Med en stærk klæbende overflade på begge sider tilbyder dobbeltsidede bånd et levedygtigt alternativ til flydende klæbemidler eller traditionelle fastgørelser som skruer, riverting, møtrikker og bolte, hvilket giver en glat, fejlfri finish. Dobbeltsidede bånd muliggør forenklede produktionsprocesser i mange sektorer, så producenterne kan lime komponenter hurtigt og rent - på både glatte og ru overflader - som f.eks. montering af batterier, linser og berøringspaneler samt sensorer og komponenter.

Hos tesa har vi udviklet et udvalg af dobbeltsidede tapes, der opfylder de krævende behov hos vores erhvervskunder. Vores højtydende dobbeltsidede tapes til generelle anvendelser spænder fra film- og skumtapes, strukturelle limbånd til aftagelige dobbeltsidede tapes. Og hvis du er på udkig efter specialfunktionalitet, tilbyder vi hos tesa jordforbindelse og elektrisk ledende, vandtætte samt termostyringsbånd til en række forskellige formål.

Egenskaber ved dobbeltsidet tape

Dobbeltsidet tape er en alsidig og nyttig klæbeløsning, der kan bruges til mange forskellige formål. De er designet til at klæbe to overflader sammen med en stærk binding, der er modstandsdygtig over for adskillelse. Dobbeltsidede tapes findes i en lang række typer og stilarter, hver med sine egne unikke egenskaber og fordele. På denne liste vil vi udforske nogle af de vigtigste egenskaber ved dobbeltsidet tape.

Få det bedste ud af dobbeltklæbende tape

Limning kan være en udfordring i næsten alle brancher i situationer, hvor forskellige materialer skal limes sammen. Desuden kræver moderne designkoncepter, at højteknologiske materialer skal limes uden at påvirke deres særlige strukturer eller egenskaber. Det er her, dobbeltsidede klæbebånd løser almindelige monterings- og fikseringsproblemer, der findes i mange produktionsprocesser.

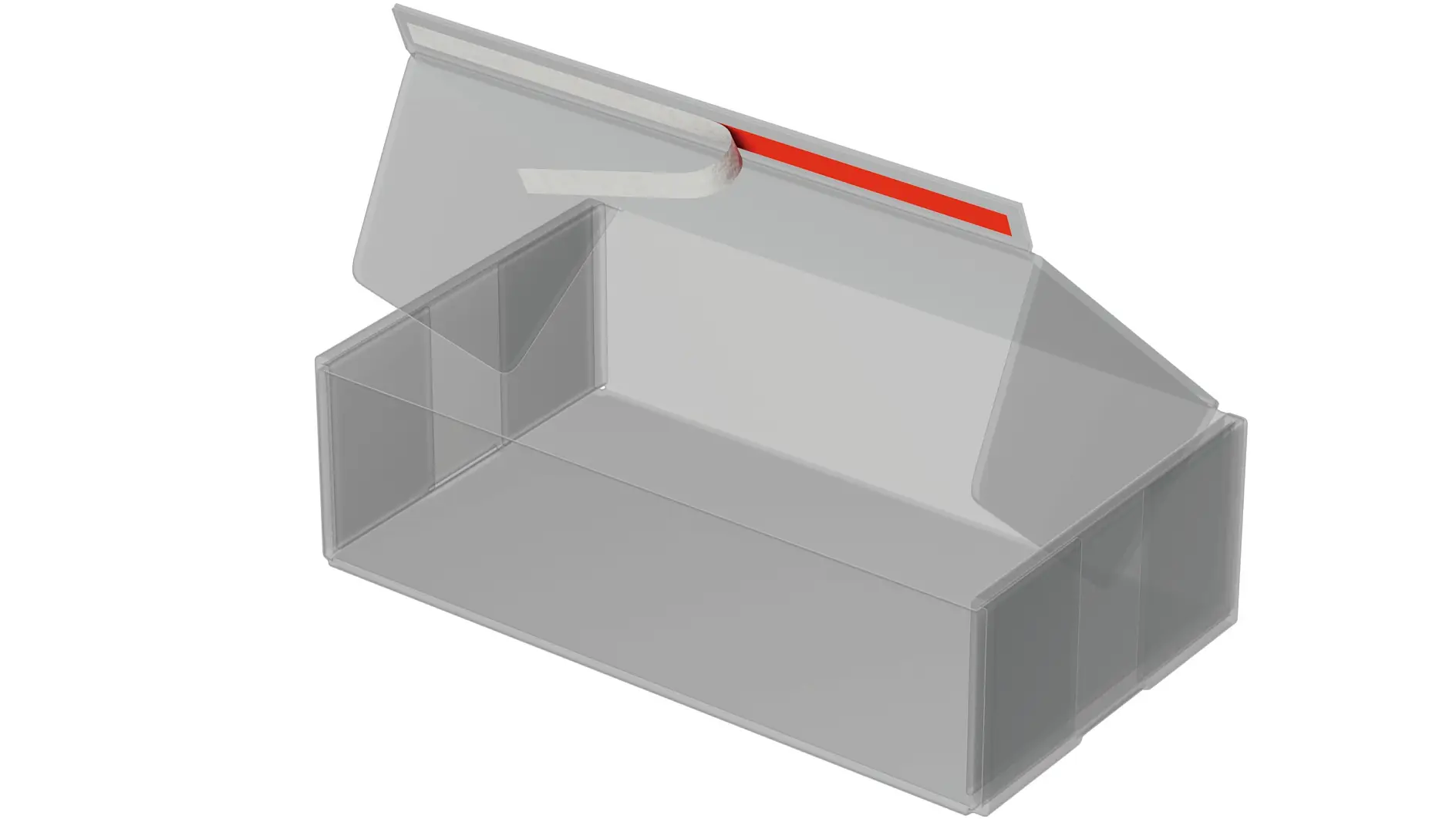

Når man limer to overflader med en dobbeltklæbende tape, placeres og fastgøres den ene side af tapen på en overflade A ved at trykke på den. Når den er på plads, fjernes tapens slipfolie, og overfladen B kan placeres på den åbne side af tapen og trykkes på plads med lige stor kraft for at sikre en god pasform.

Når en mindre genstand skal placeres på en flad overflade, er det normalt mere effektivt først at sætte tapen fast på den genstand, der skal sættes på plads. Det reducerer mængden af tape, der skal bruges, og hjælper med at sikre, at emnet placeres korrekt.

Potentielle industrielle anvendelser for dobbeltsidede bånd

Dobbeltsidede tapes er et populært valg i industrien på grund af deres unikke egenskaber og fordele. De giver en stærk og pålidelig binding, der kan modstå barske miljøer og ekstreme temperaturer. Dobbeltsidede tapes af industriel kvalitet er designet til at give langvarig vedhæftning, hvilket gør dem ideelle til brug i krævende anvendelser som bilindustrien, elektronik, apparater, bygningskomponenter og rumfartsindustrien.

Oversigt over dobbeltsidede bånd

Udvalget af vores dobbeltsidede tape tilbyder dokumenteret pålidelighed og højtydende vedhæftning, der opfylder krav fra producenter over hele verden. Vi anerkender dog , at hvert projekt er unikt og har specifikke krav. Derfor er vores eksperter glade for at udvikle skræddersyede løsninger sammen med dig og hjælpe med at finde den rigtige klæbeløsning til din specifikke brugssituation. Find en oversigt over vores dobbeltklæbende tapeløsninger nedenfor:

Formular til industri produktvælger

Dobbeltsidet tape: OFTE STILLEDE SPØRGSMÅL

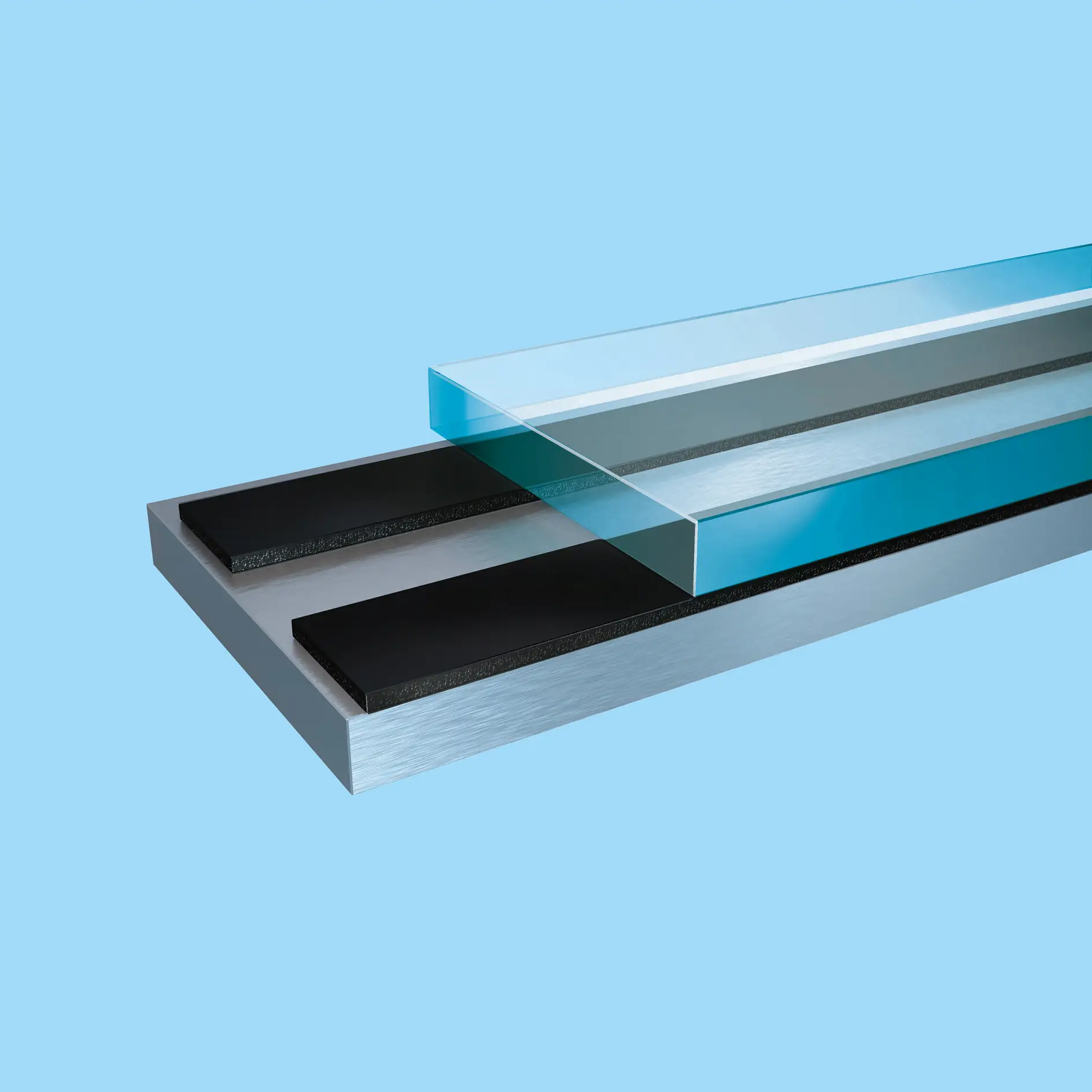

What is an adhesive tape carrier, and do all double-sided tapes have one?

A carrier is a thin backing on which the adhesive is spread. This carrier could be made of one of several materials: paper, film, fabric, acrylic foam, foil, or non-woven fibers. All double-sided tapes have a carrier which also helps further strengthen the bond. The choice of double-sided tape with a specific carrier depends on the application as each material brings particular properties to the tape.

What is the difference between a double-sided tape and an adhesive transfer tape?

Double-sided tape has adhesive on both sides of a carrier, allowing each surface to bond securely to the tape. The tape’s carrier also provides additional structural support. Adhesive transfer tape, however, has no carrier and just relies on the strength of the adhesive to form a bond. In return it offers an increased conformability and wetting performance.

Why choose a double-sided tape for industrial applications?

Our extensive track record has allowed the experts at tesa to test our adhesive tapes against other types of bonding systems over many years. And based on our experience, the advantages of double-sided tapes are clear when meeting the challenges of today’s complex, optimized production processes. For example, double-sided tapes can greatly reduce common health risks related to liquid glue solutions and can be easier to handle. Moreover, double-sided tapes can even carry more weight than using regular screws in certain scenarios and provide more design freedom in manufacturing processes.

What are the advantages of double-sided tape?

Double-sided tapes are used in many applications in a range of industries. Some are ideal for bonding to flat smooth surfaces such as glass, metal, and non-embossed plastics. Others are ideal for rough, irregular surfaces. All tapes generally offer a good temperature resistance, and they are easily integrated into current production lines. Double-sided tapes can absorb shocks and vibrations and are relatively easy to remove, if needed.

How can double-sided tape be removed?

tesa® double-sided adhesive tapes provide strong hold on various surfaces, even for heavy duty applications. Many of our products can be removed easily and without leaving any residue, when needed. Over the last decades we have developed a broad range of double-sided tapes that can be debonded in different ways, e.g. by peeling, by applying solvents or by stretching (tesa® Bond & Detach). As debonding is becoming increasingly important we are constantly developing new methods. Please contact us to learn more.