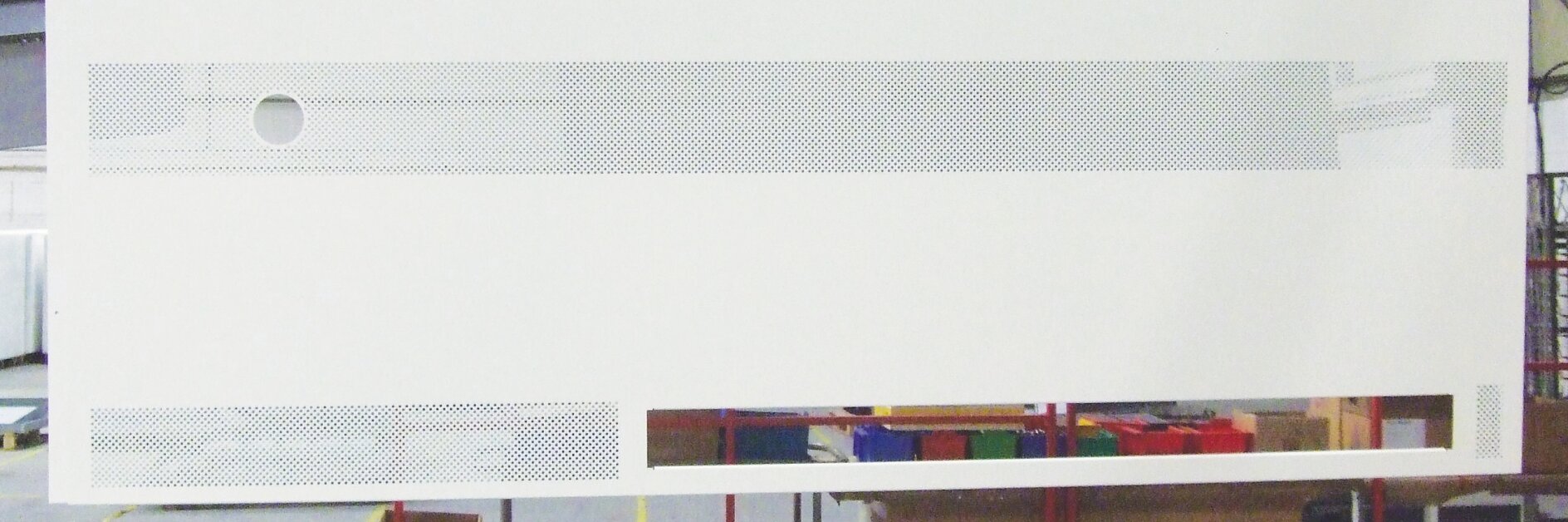

tesa® ACXplus 7074, a new category of double-sided adhesive tape for high performance constructive bonds, is being used by a sheet metal manufacturer to bond profiles onto ceiling panels that typically house air conditioning units or lighting assemblies.

In the sheet metal industry, the ability to provide optimal wetting of different surfaces while also absorbing dynamic forces and vibration has been identified as a key factor, especially in panel bonding applications.

Application and Current Method

On this particular application, the customer was bonding profiles to panels using a conventional liquid adhesive, prior to powder- coating.

Customer Issue

Applying the liquid adhesive was found to be somewhat laborious, involving a relatively cumbersome jig and clamp in order to accommodate a six-hour cure time, in addition to presenting some health and safety issues.

tesa Assessment and Proposal

The tesacohesion team considered the process as a whole and engaged with the customer in an assessment and testing programme using 12mm tesa® ACXplus 7074 as an alternative solution.

tesa® ACXplus 7074 consists of a high performance acrylic system defined by the strength of its bonding power. It also offers viscoelastic properties, with elastic restoring forces that provide inner strength and viscous characteristics which relax mechanical stresses, to create a dimensionally stable and permanent bond.