Without UV protection, displays will lose brilliance and quality of image, and the material itself will degrade, potentially even yellowing over time. A polarizer film is the piece most commonly used in the display stack to block out the worst of the UV light. But a polarizer’s thickness – just a fraction of a millimeter – can still add unwanted thickness. Furthermore, its relatively low aging performance – particularly at temperatures above 95°C – leaves engineers in search of an alternative.

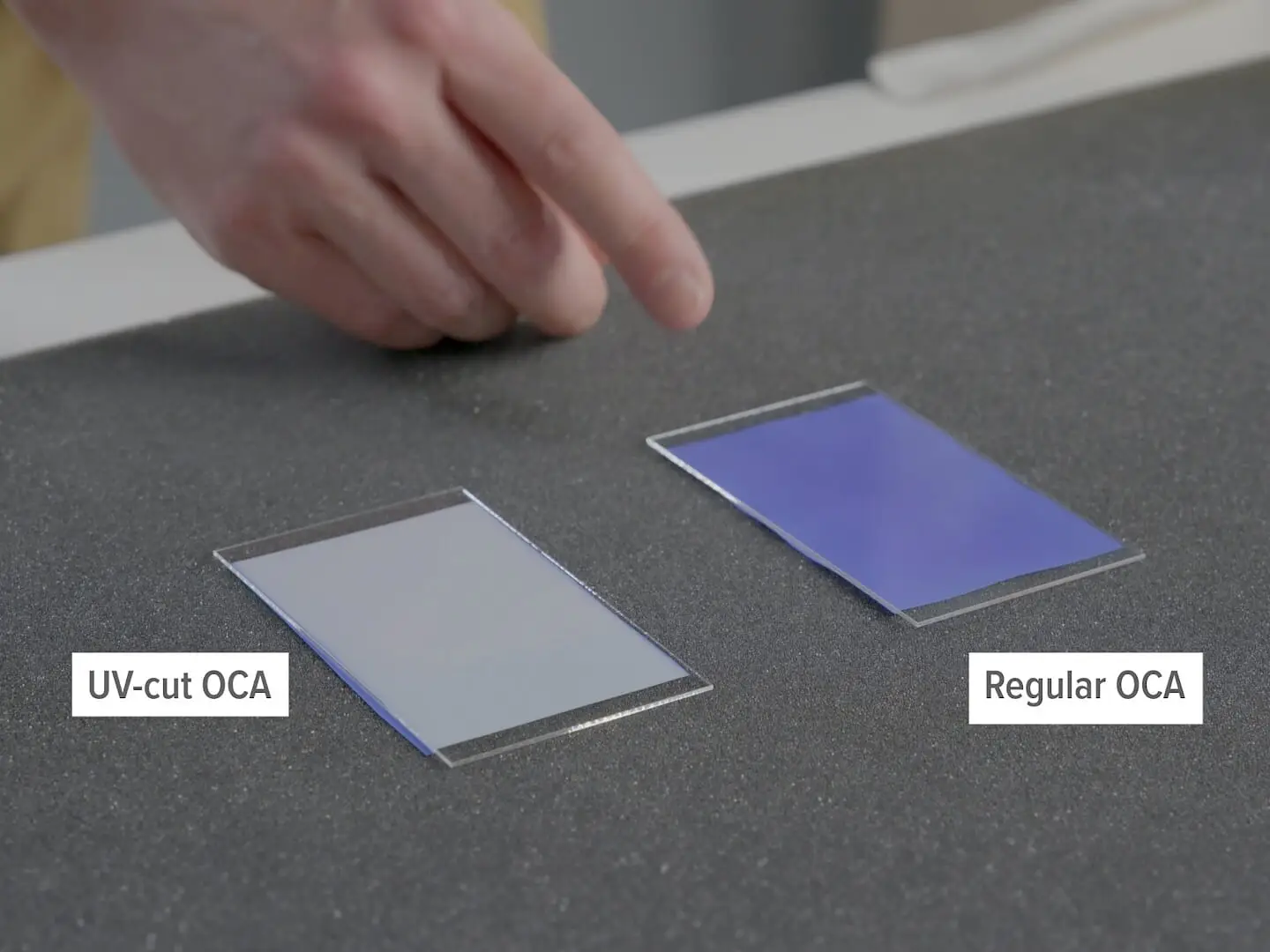

However, tesa has produced an Optically Clear Adhesive (OCA) that combines adhesive strength with added properties such as UV resistance. Testing shows our tesa® 88910 adhesive material blocks transmittance of UV light below a wavelength of 380 nm, while achieving a transmittance of visible light over 99 %. A UV-vis spectrometer was used to gather results, at conditions of 23 °C and 50 % RH. Only the adhesive itself was tested, without a liner or glass.