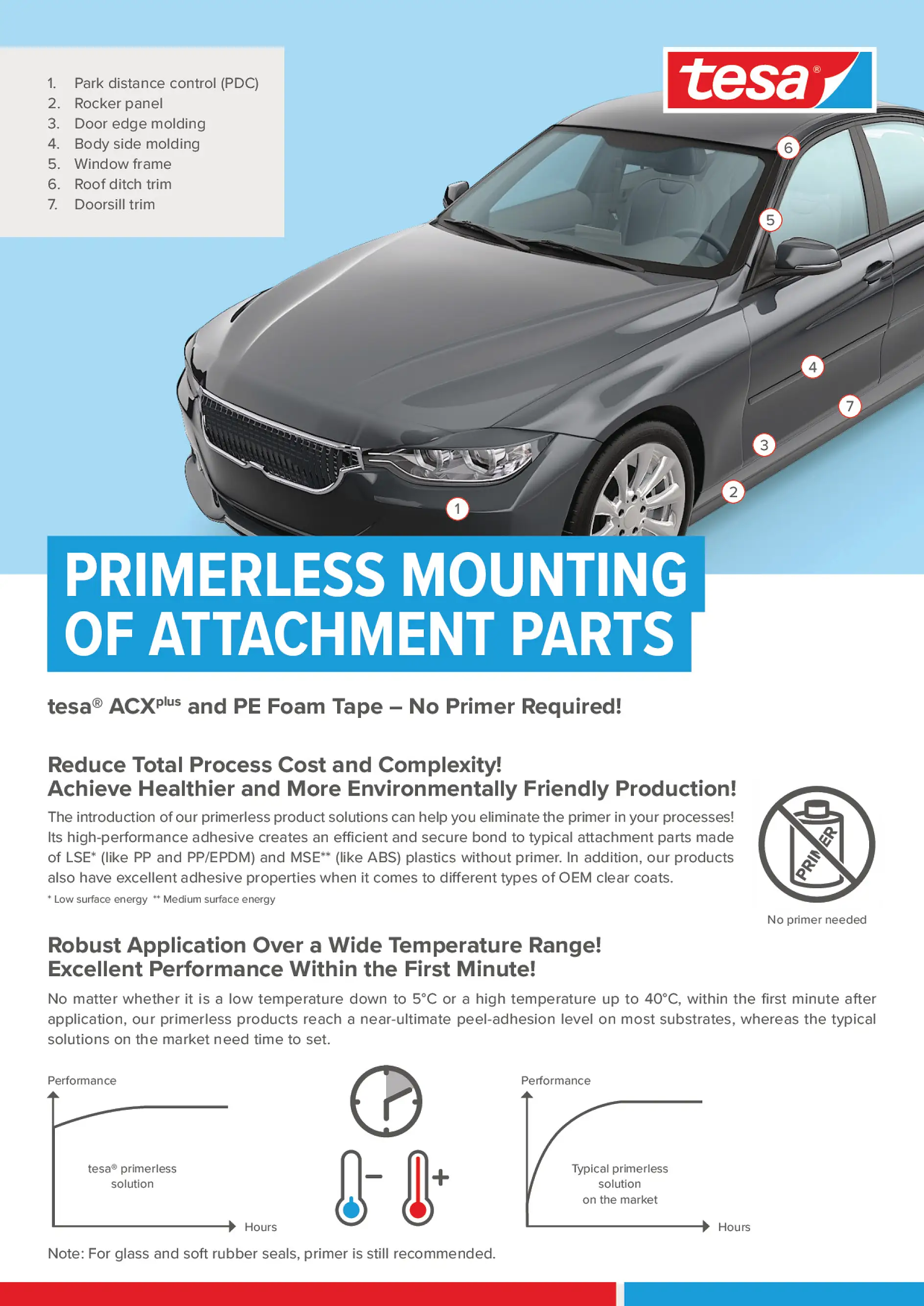

Constructive bonding of attachment parts to car bodies can be very challenging. Dissimilar materials like plastics, metal, and glass have different coefficients of thermal expansion, so when they warm up or cool down, they expand and contract at different rates. In addition, parts that need to be bonded to a vehicle’s exterior have different levels of surface energy. Acrylic foam based adhesive tapes, thanks to its viscoelastic feature, join materials gently and permanently. For this reason attachment parts like emblems, body side moldings, sills, and bumpers can be securely mounted to exterior car body surfaces and withstand all external influences throughout the vehicle’s lifetime.

Developed for the permanent mounting of LSE and MSE plastic substrates and clear coats

tesa® ACXplus Primerless Line is our new category of high performance tapes for exterior attachment part mounting. Because it is primerless, this double-sided acrylic foam tape delivers a permanent bond from the moment it’s applied – without the need for primer. Applying primer as part of the attachment part mounting process is an expensive, time-consuming, and hazardous process. So if you can eliminate the primer in production, you get bottom line benefits from greater process efficiency and a lower total process cost. On top, no matter whether it is a low temperature down to 5°C or a high temperature up to 40°C, within the first minute after application our primerless products reach a near-ultimate peel adhesion level on most substrates, where as the typical solutions on the market need hours to days for achieving ultimate performance. At the same time, the more environmentally friendly production line helps you meet stricter environmental standards and provide healthier working conditions.