Given that no disposable tapes are required, tesa® Twinlock aligns perfectly with Orion’s Good Packaging initiative by improving the company’s carbon footprint. Choosing this solution over standard sleeves also saves the company time. Typically tesa® Twinlock takes three minutes to mount versus an average of 10 minutes for regular solutions.

The company also saves costs and further waste by not having to purchase tape that is needed for other flexo solutions.

Switching to tesa® Twinlock was a significant decision for Orion. Fortunately, considerations such as past track record, ensuring uptime, return on investment, and the availability of technical support are items tesa® consistently delivers to its customers.

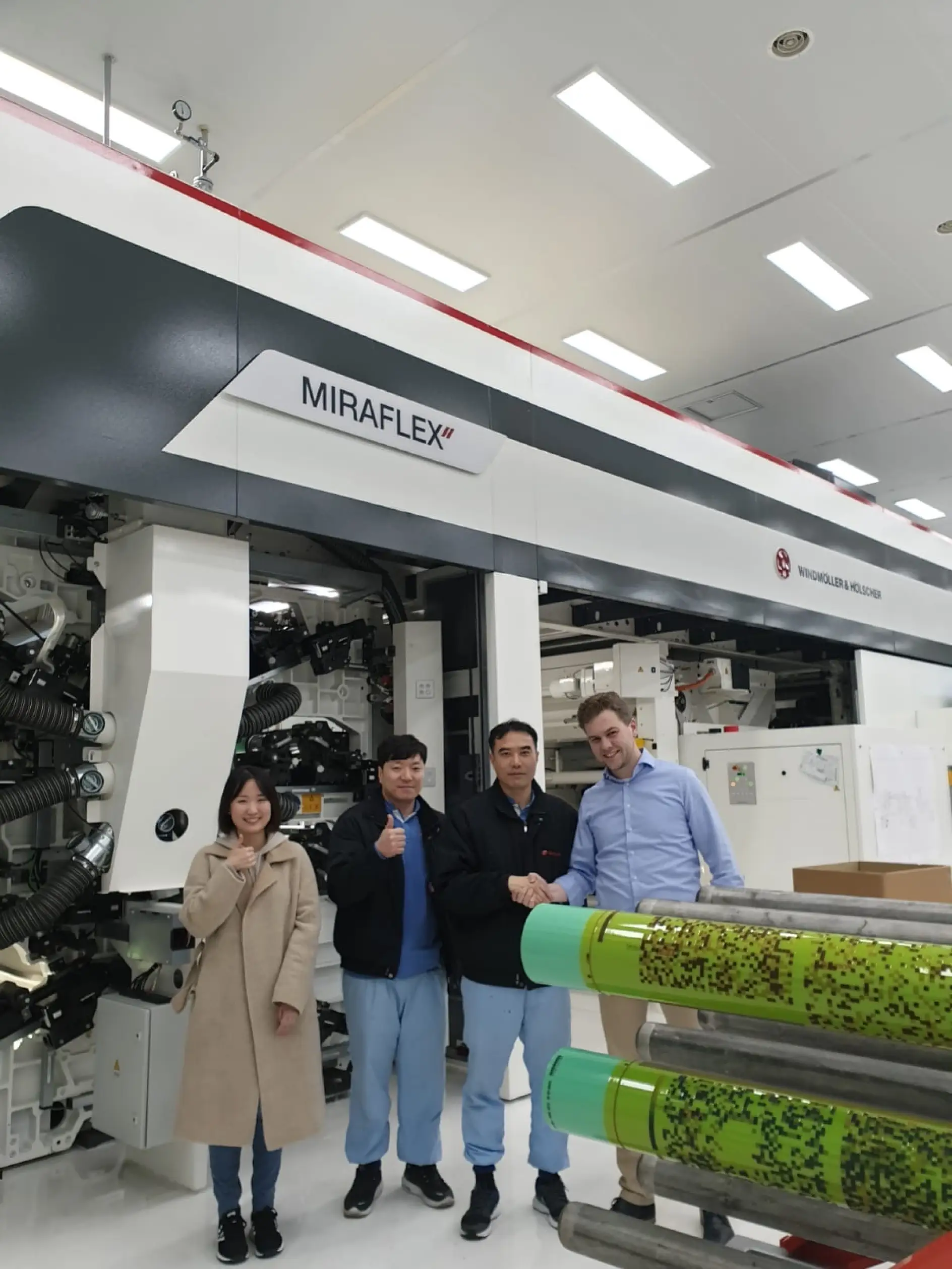

During the procurement process, tesa® invited Orion representatives to the company’s headquarters in Germany. Here they were able to better understand the capabilities of tesa® Twinlock while experiencing how European printers are prospering with the solution. Later, an engineer visited Orion’s plant in South Korea for three days to provide training for staff. tesa® also provided standard operating procedures in Korean to ensure that there were no misunderstandings. In addition, Orion receives ongoing technical support from tesa®.

The forging of such partnerships is nothing new to tesa®, nor is the servicing we provide to customers. Since our founding more than 120 years ago, and through our continued investment in research and development activities, our corporate strategy is to support the long-term goals, actions and successes of our customers — as they strive to become more productive, safer and do their bit for the environment and society.