Lay-Up and Infusion Process

The lay-up and infusion process is at the core of blade production – make your processes fast and reliable.

The lay-up and infusion process is at the core of blade production – make your processes fast and reliable.

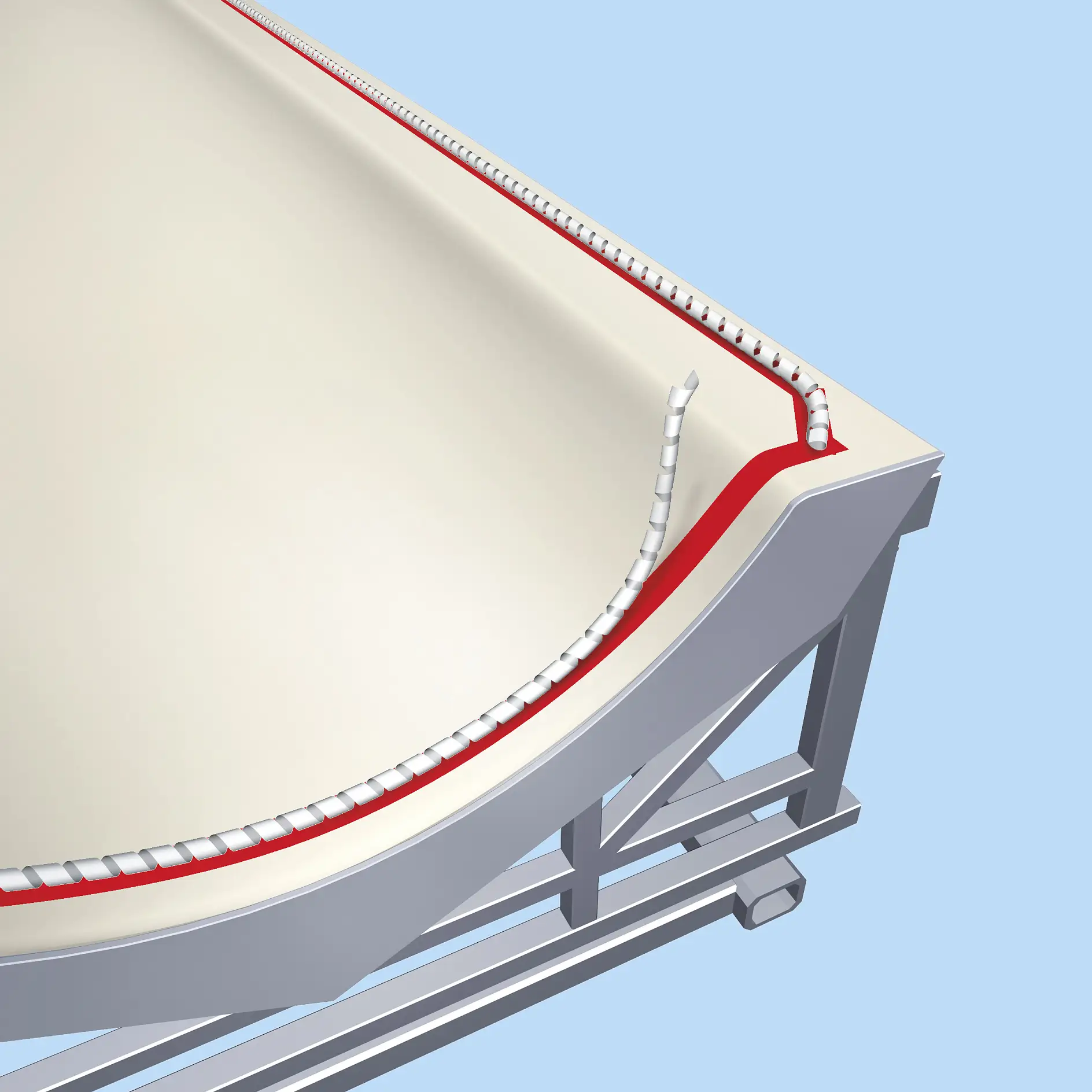

Flash breaker tape

Our range of single-sided PET tapes with silicone adhesive are designed for masking applications around the mold during resin infusion. They adhere well to molds treated with release coats, can be removed without tearing, and protect the mold from flashed resin. They are available in various colors and thicknesses for either higher conformability or greater tensile strength.

Product features:

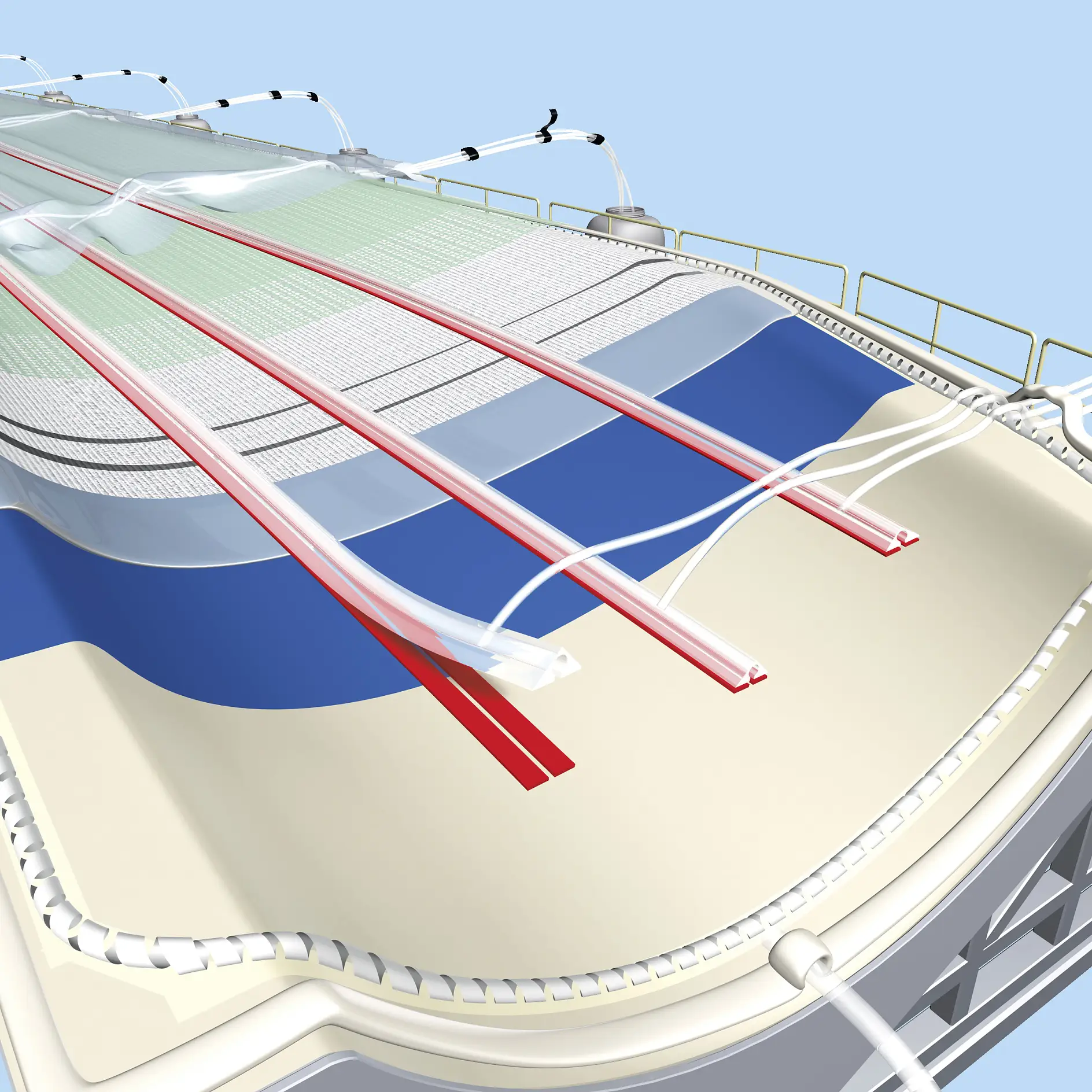

Fixation of resin infusion profiles

Our selected double-sided tapes are a trusted solution for fixing plastic resin infusion channels to the resin distribution net. They can be applied quickly and reliably, which leads to a more homogenous resin distribution. We have tapes with different levels of adhesive on each side for better removability.

Product features:

Good immediate adhesion

Trusted solution for blade production

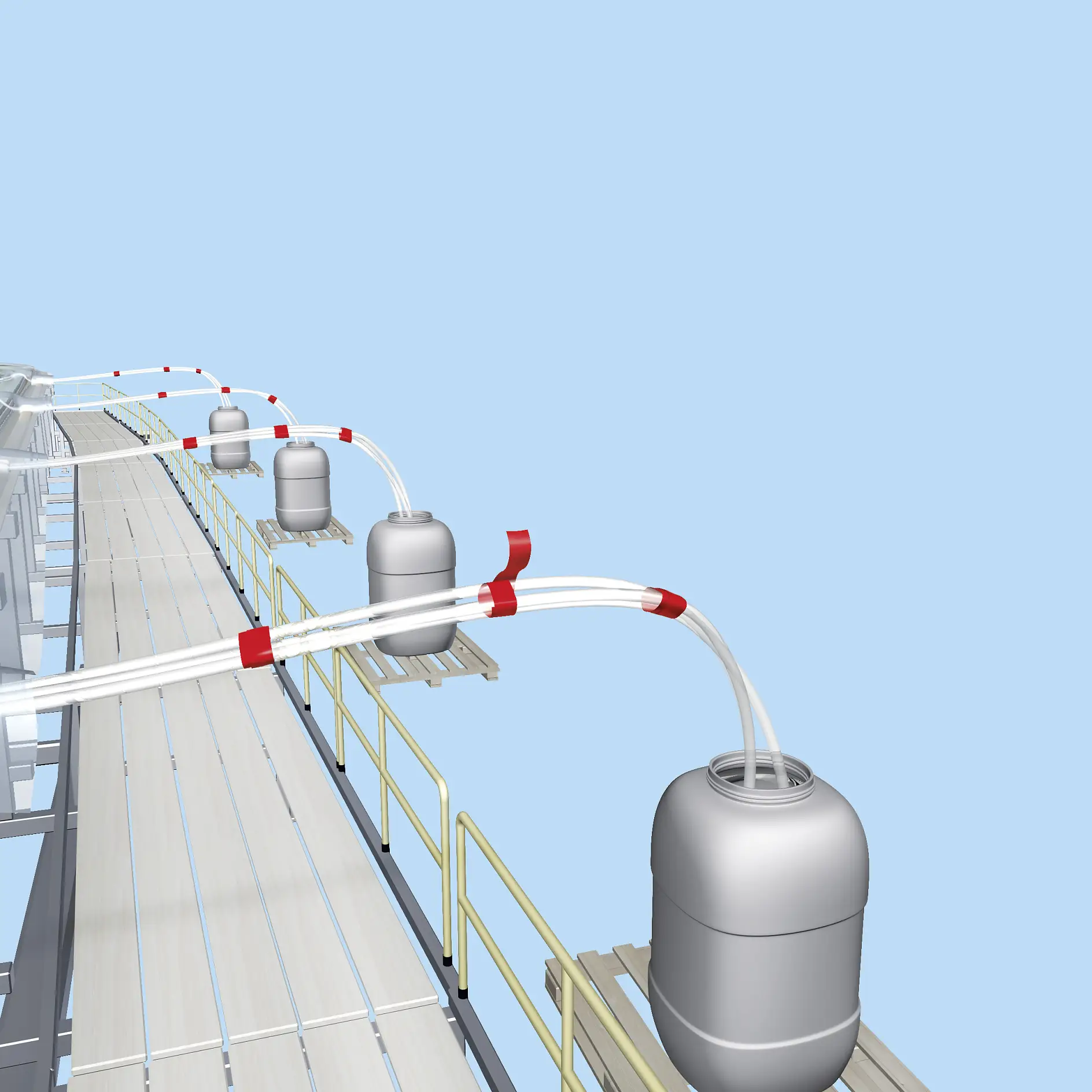

Bundling of tubes

Our single-sided duct tapes feature an aggressive tack even on rough surfaces. They are easy to tear by hand and can be used for a wide range of fixing and bundling applications on the shop floor.

Product features:

High adhesion

High tack

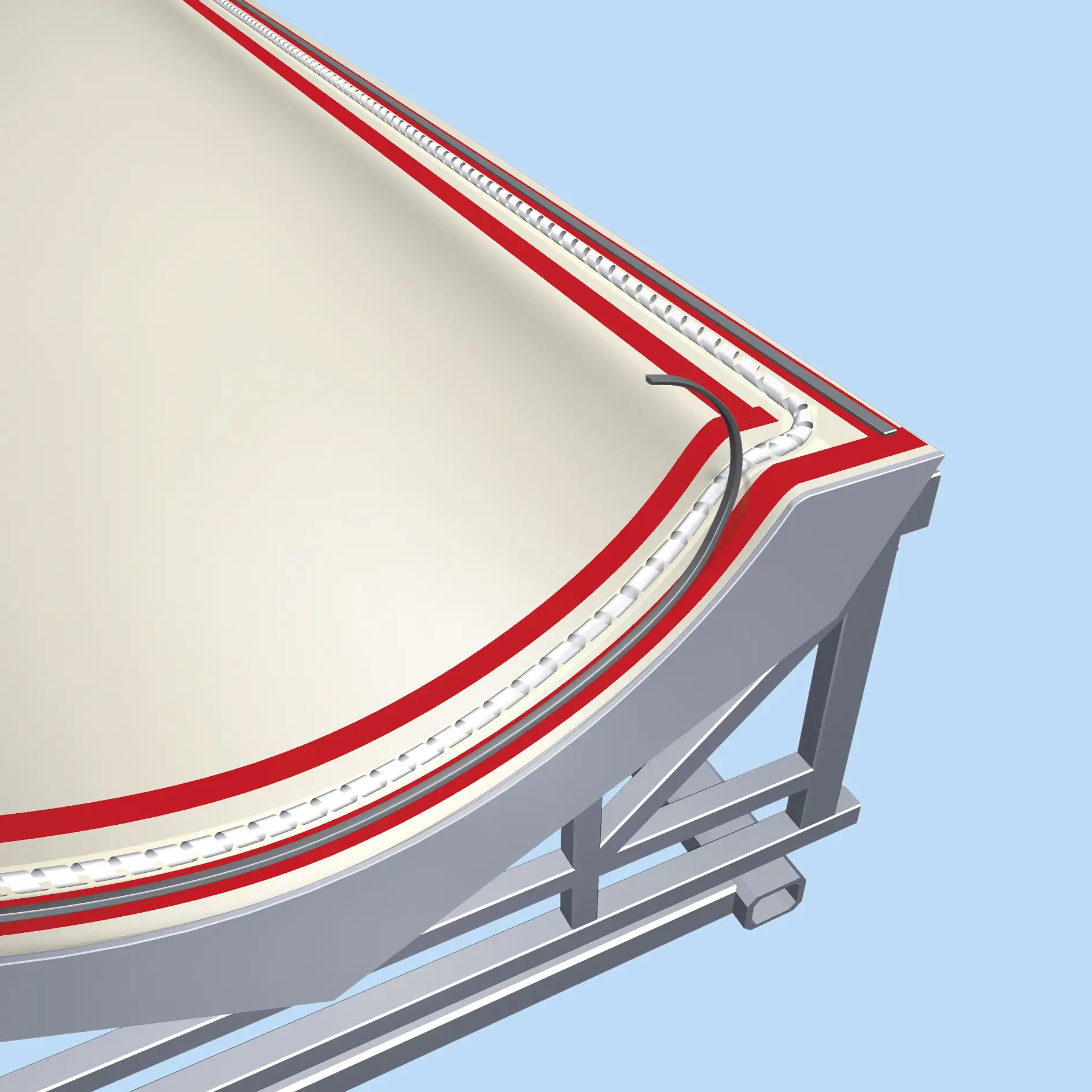

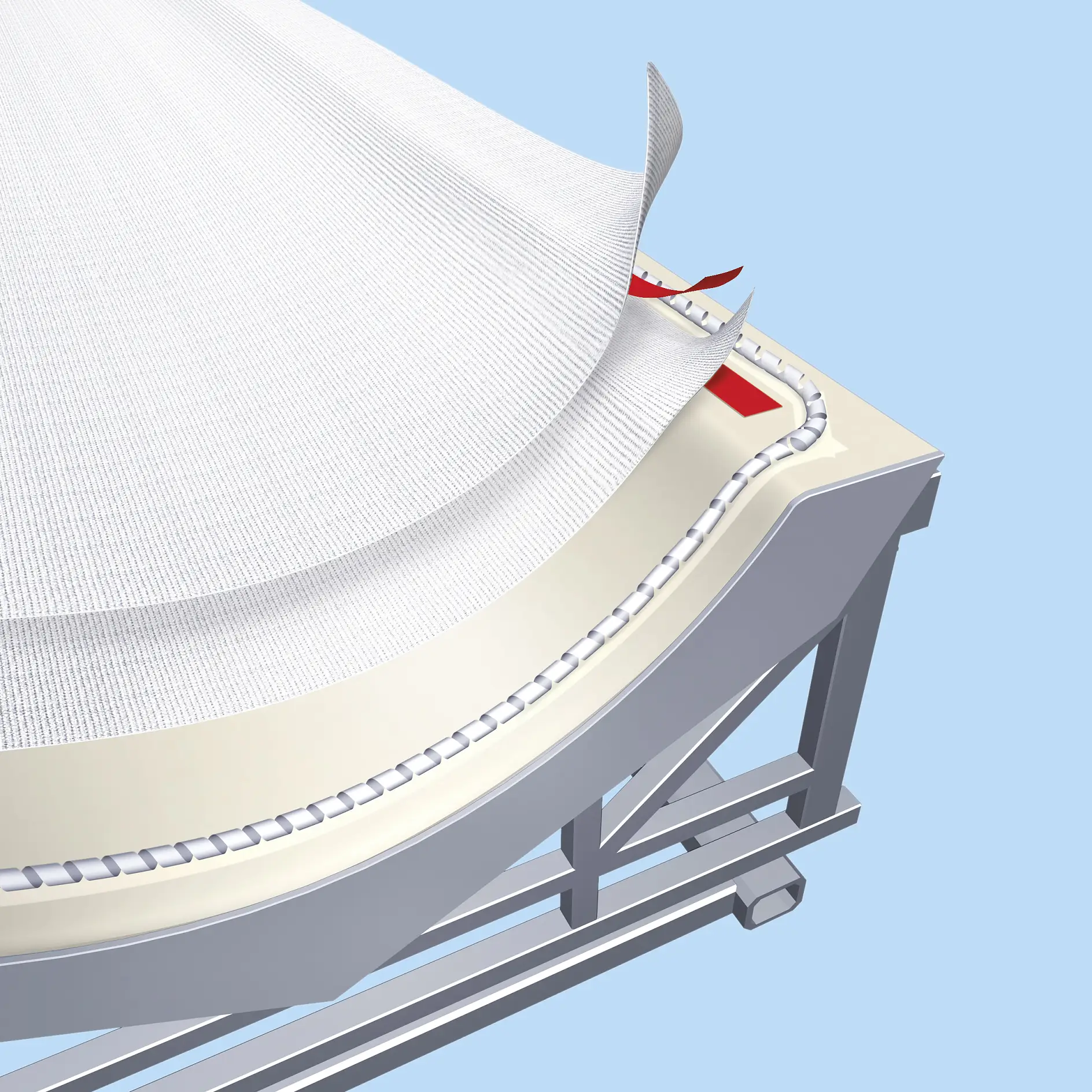

Vacuum spirals

There are several methods to form the vacuum channels. If you want to fixate vacuum spirals to the mold, then choose one of our double-sided tapes. The tape will need to bond well to the mold as well as the vacuum spiral so that there is no displacement during mold preparation and resin infusion. Using a tape that can be removed without leaving any residue reduces the time needed for the next mold preparation cycle.

Product features:

High immediate adhesion

Good removability

First layer fixation

The blade consists of numerous layers of glass fiber. Our customers use different methods in order to prevent the web from slipping into the mold during layup. At the edge of the mold, tesa double-sided adhesive tapes can be used to fix the first layer as well as the following layers to each other. Which product is used depends on requirements for removability and temperature resistance. Please contact us for more information.

Product features: