Automated tape solutions for headliner applications

Markets

Mission accomplished: tesa and Bertrandt improve headliner assembly process

In collaboration with Bertrandt, a leading technology development service provider in the automotive sector, tesa has refined the automated assembly of headliners in cars. Up to now, mainly hotmelt solutions have been used for mounting cable harnesses and other parts to the headliner.

Together, both companies have now evaluated the performance of a new automation process, enabled by tesa® 50400, a double-sided adhesive tape with high initial adhesion. Independent analysis using virtual simulation and methods-time measurement (MTM) revealed outstanding results: The automation process with tesa® 50400 leads to a significant saving in the cycle time of the process for example by eliminating the need for curing, as is necessary with a hotmelt solution. Process cleanliness can also be improved, and the necessary reworking reduced or simplified.

Easy and fast headliner assembly

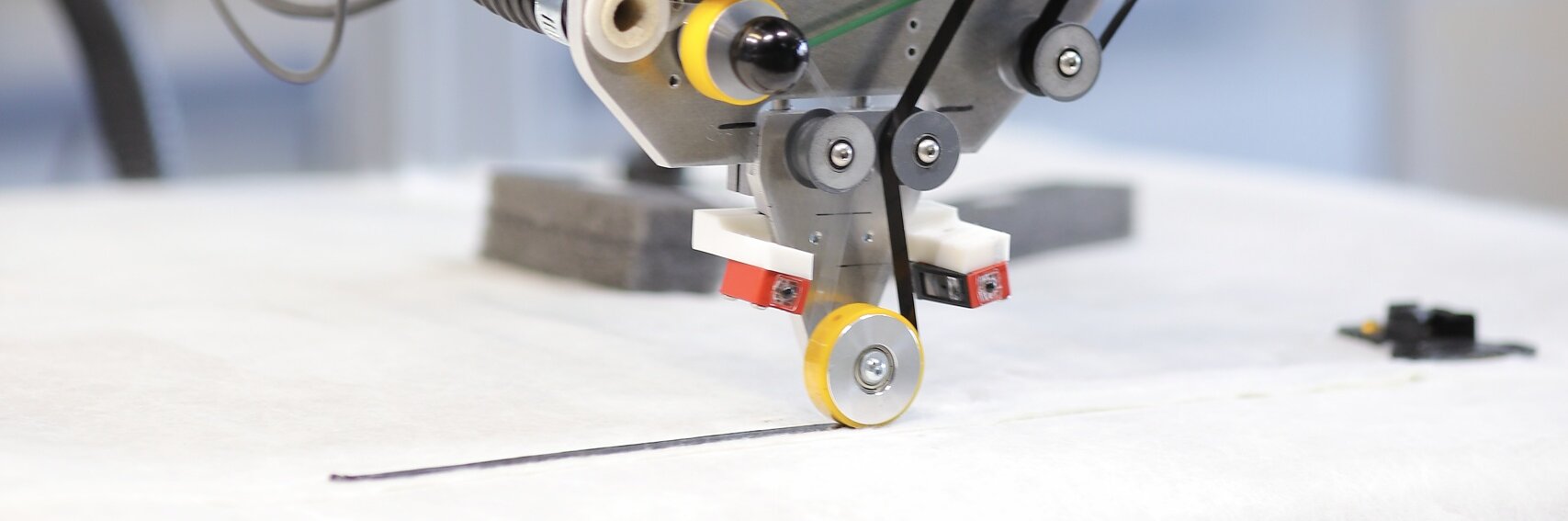

Automated headliner assembly

tesa® 50400 double-sided cable mounting tape

- Excellent bonding on rough, irregular, and nonpolar surfaces

- High tack

- Highly conformable

- Repositionable