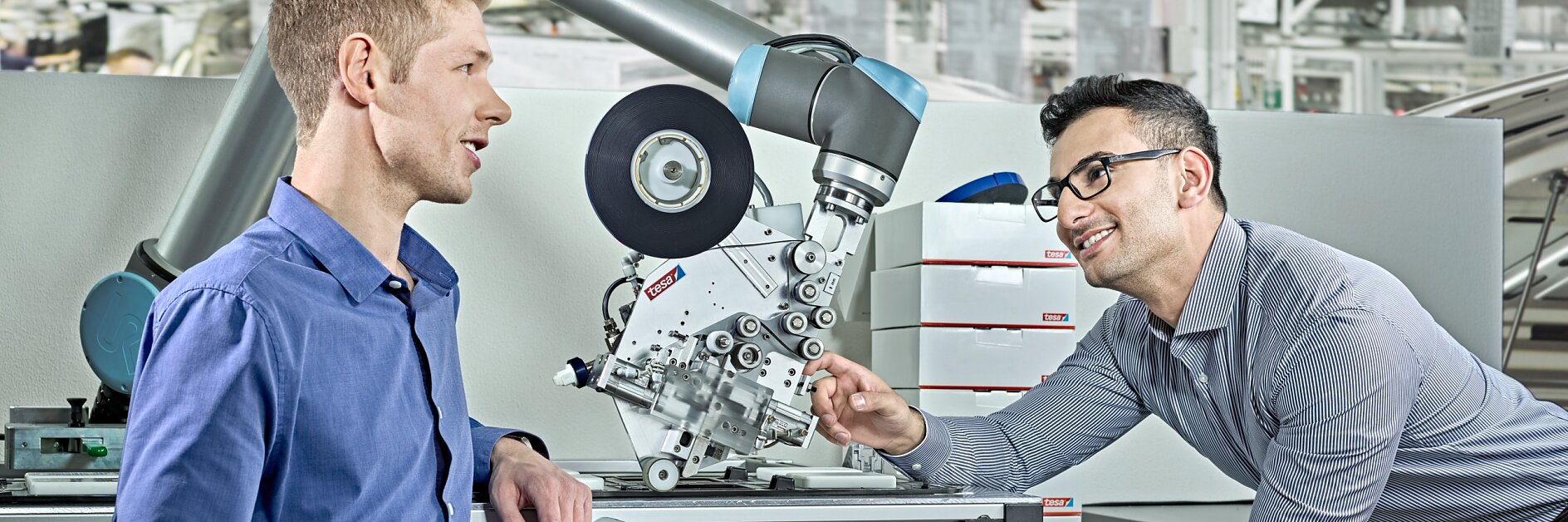

As the pace of technological innovation continues to drive the automotive industry in exciting new directions, manufacturers are looking for suppliers who do more than just supply a product. At tesa, we are a known leader in technical adhesive solutions, and given our knowledge base, strong market intelligence, and a global R&D team, we can collaborate with OEMs and tiered suppliers in a closed loop of identifying and implementing application solutions. From brainstorming on specific applications to internal testing and trials, our highly trained sales force works closely together with our customers’ engineers, tiered suppliers, and tesa’s R&D staff to help our customers achieve greater operational efficiency, weight reduction, cost savings, and product quality.

Custom Application Solutions for the Global Automotive Industry

Technologies

Given our knowledge base, strong market intelligence, and a global R&D team, we can collaborate with OEMs and tiered suppliers in a closed loop of identifying and implementing application solutions.

Our Process Expertise Improves Both Process Efficiency and Quality

Let’s Develop the Perfect Application Process

Because tesa is one of the world’s leading producers of self-adhesive tapes, we bring a deep expertise to a wide range of automotive applications, which lets us quickly design and implement the best application solution possible. Our external engineering partners, worldwide teams of process engineers, and sales representatives are always available to carry out in-depth on-site analysis of the individual application and recommend improvements in the technical, process, and production requirements.

Our Application Solutions for the Automotive Industry

Attachment Part Mounting

We offer a wide range of application solutions for the efficient attachment of car body parts. From a pre-production step at a tier supplier to the direct application onto the vehicle, we excel in developing an application process to suit your specific production needs – one that ensures accurate placement and secure bonding.

Primer pens for manual or automated application

Used to improve the adhesive bonding of the tape onto difficult surfaces.

Tabbing solutions, including cutters

Used to create finger-tabs for a more efficient liner removal.

Handheld application devices

For efficient and accurate tape placement.

Pressurizing tools

Used to pressurize tapes to the attachment part, or to attach parts to the car body.

Stationary devices

For fast and efficient dispensing of die-cuts.

Fully automated systems

For the quick and precise application of mounting tapes.

Cable Mounting

Whether you want to apply your cables onto headliner materials, plastic parts or door modules, our cable mounting tape dispensers support your production process to ensure a smooth supply of tape.

Stationary tabletop devices

For the easy and efficient dispensing for cable mounting tapes and die-cuts.

Easy to remove cartridges

Allows a simple roll exchange ensuring a continuous supply of tape.

Interior Mounting

We offer a range of universal and custom-made handheld devices for precise and reproducible tape positioning.

Handheld applicators

Available for pre-production steps at tiers or the direct application at the OEM assembly line.

Hole Covering

Our devices for hole covering applications provide real time savings in your production. They ensure more efficient, ergonomic tape handling and can be used on moving our stationary vehicles. Fully automated hole covering application systems can be developed together with our experienced partners.

Lightweight handheld devices

Ensures the easy dispensing and application of die-cuts onto the car body.

Stationary table top dispensers

Allows multiple dispensing of hole covering die-cuts with easy liner separation.

Pre-loaded cartridges

For a quick and simple roll exchange in the dispenser.

Permanent Paint Protection

When working with highly transparent films in visual areas, it is particularly important that the tape application can be done accurately and without material contamination. Our tools and handheld devices support a crease-, bubble-, and fingerprint-free application to ensure optically clear results.

A range of squeegees

Enables you to squeeze out any air bubbles trapped under the film without damaging the surface of the optically clear film.

Specially designed u-profile tools

Used for the secure bonding and bubble-free tape application over difficult profiles.

Handheld devices

For the fast and precise application of a variety of tapes for u-profile applications.

Design Masking

For two-tone painting of the car body, design painting of attachment parts, flange masking, and large area masking, we offer a safe, efficient application of all of our masking tapes.

Available devices range from handheld tools to fully automated solutions.

Temporary Surface Protection

We support the efficient application of our protective films onto the vehicle with our range of squeegees, cutters and dispensers, both manual and automated.

Manual and fully automatic tape dispensers.

A range of squeegees

Used to press the protective films firmly onto the vehicle.

Specially designed knives

For the easy and precise cutting of protection films.

A Trusted One-Stop Resource for Application Solutions

From protection during transport and securing cable sets to permanently adhering components, tesa offers global automotive OEMs a wide range of innovative, reliable, high quality self-adhesive products – but we don’t stop there. Our process expertise and application solutions help our customers improve process efficiency and quality while reducing the process time. This seamless offering creates real synergy across the entire auto manufacturing process, which provides you with a true competitive advantage.