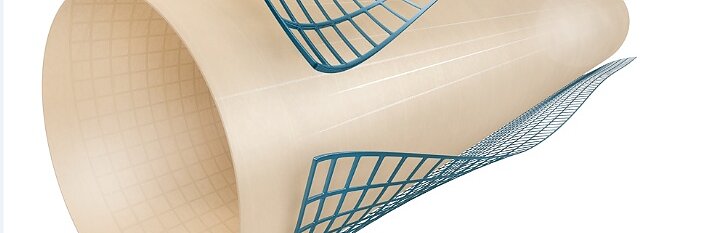

FLEX Design: For Thin-walled and Scratched Sleeves

Technologies

The flexible packaging industry is continuously working to increase productivity on the shop floor level. We support this objective with the introduction of our product line tesa Softprint® FE-X, combined with our new FLEX Product Design for maximized Efficiency.

Benefits of FLEX-Design

Use of Thin-walled Sleeves

Product Feature

More flexibility in the horizontal direction, which compensates for differences in the sleeve circumstance during the mounting process onto thin-walled sleeves.

Customer Benefit

- Better tape bonding on thin-walled sleeves

- No press downtime

Use of Scratched Sleeve Surfaces

Product Feature

Alligned combination of a more flexible product design and specially-engineered adhesive on the sleeve side, achieving better bonding on inconsistent surfaces.

Customer Benefit

- Better bonding on inconsistent sleeve surfaces

- No press downtime

Benefits of tesa Softprint® FE-X Adhesives

tesa Softprint® FE-X plate mounting tapes don´t just hold down plate edges effectivity during standard conditions. Our engineers have developed a plate mounting tape which also offers the best plate bonding during in press cleaning with solvents and at high temperatures and humidity. Furthermore, to optimize the print job preparation, the plate side adhesive of tesa Softprint® FE-X comes with a non-tacky surface characteristic to mount multi-color jobs faster into register. These benefits make tesa Softprint® FE-X simply productive for every printer!

Benefits of tesa Softprint® FE-X Adhesives

Benefits of tesa Softprint® Foam Quality

Our smart tape production process leads to more intact foam cells for better cushioning and resilience over time – providing excellent print quality.

Furthermore the combination of tesa Softprint tapes with the latest plate technologies and high quality printing presses allows the best print quality for combination motifs when selecting only one foam hardness. This enables printers to reduce process complexity and offers more standardized print production.

Benefits of tesa Softprint® Foam Quality