Huayang taking great strides in CI flexo press perfection

Technologies

About Huayang

Huayang unveiling the new CINOVA.S at drupa 2024

Since the initial release of their CINOVA CI flexo press in 2019, Huayang has continuously strengthened its production and research capabilities and upgraded the performance of the CINOVA CI flexo press.

They are now ready to showcase the new CINOVA.S at drupa 2024. CINOVA is mainly used in industries such as corrugated box preprinting, paper cup and paper bag printing, plastic food packaging, and sanitary product packaging.

Meet Huayang at drupa 2024: Hall 15, booth C05

Our interview

In an interview beginning of 2024, we were able to ask Mr. Chen Long, ‘Head of Engineering Flexo Printing Project’, about their latest developments and his experience with our self-adhesive solutions.

Can you share the motivation to design the new CINOVA.S?

Providing printing customers with a high-speed, stable, and reliable flexographic printing equipment, helping our clients achieve stable and excellent printing results while meeting efficiency requirements. This drives the industry's transition from gravure to flexo, while also bringing higher product value to brand owners. This is the original intention behind the development of our CINOVA flexo press series.

What are the highlights of the new CINOVA.S?

We have comprehensively optimized the performance of CINOVA.S, mainly in the following aspects:

- Increased speed: The new CINOVA.S series achieves higher printing speeds, reaching up to 600 meters per minute.

- Improved stability: The new CINOVA.S optimizes the design of the print units and printing pressure, the ink supply system is more stable and accurate, thus better meeting the requirements for high print quality in the transition from gravure to flexo.

- Enhanced drying capability: The optimized drying system can meet the drying requirements for both water-based and solvent-based inks at a speed of 600 meters.

- High level of automation: The automation level has been improved to enable automatic pre-adjustment of pressure and registration upon startup. CINOVA.S can also be connected to automated sleeve loading equipment and can realize automatic rewinding with AGV.

Of course, we will continuously collaborate with industry partners to explore flexo solutions and provide value-added services to our customers.

How is the overall performance of tesa® adhesive solutions on CINOVA.S?

© Huayang

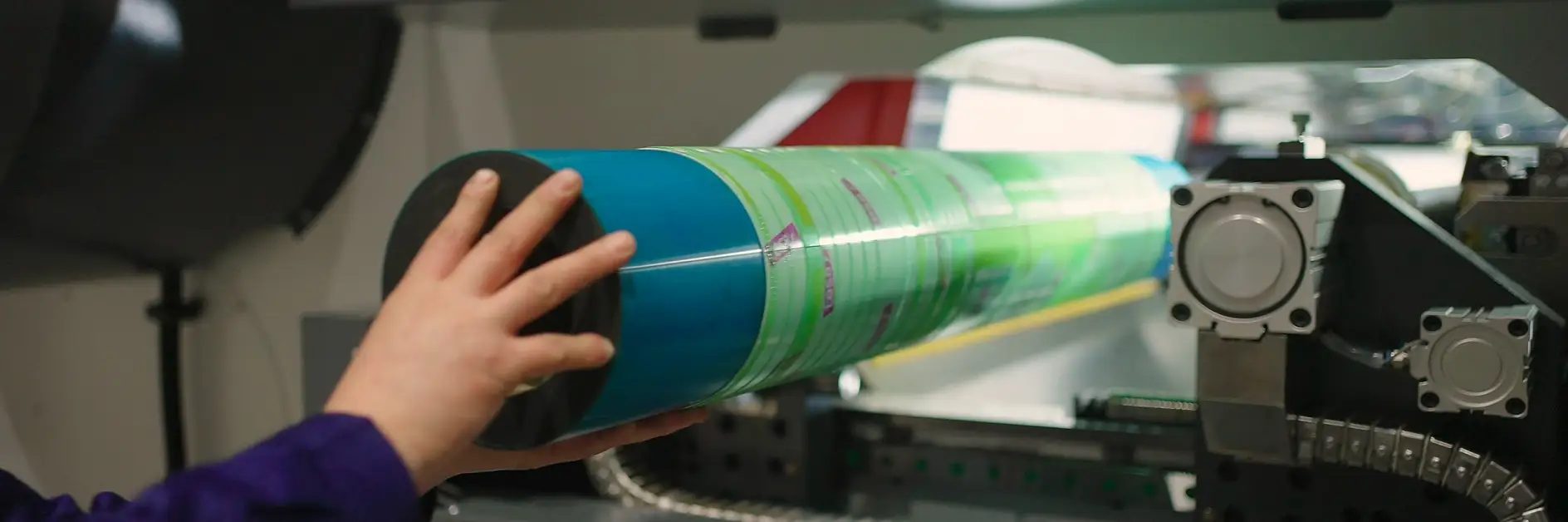

tesa® plate mounting solutions

Our printing tests show that tesa® Twinlock self-adhesive sleeves and tesa® Softprint plate mounting tapes both provide excellent print results. tesa® Twinlock self-adhesive sleeves ensure good print results, while also providing a simple and convenient plate mounting process.

© Huayang

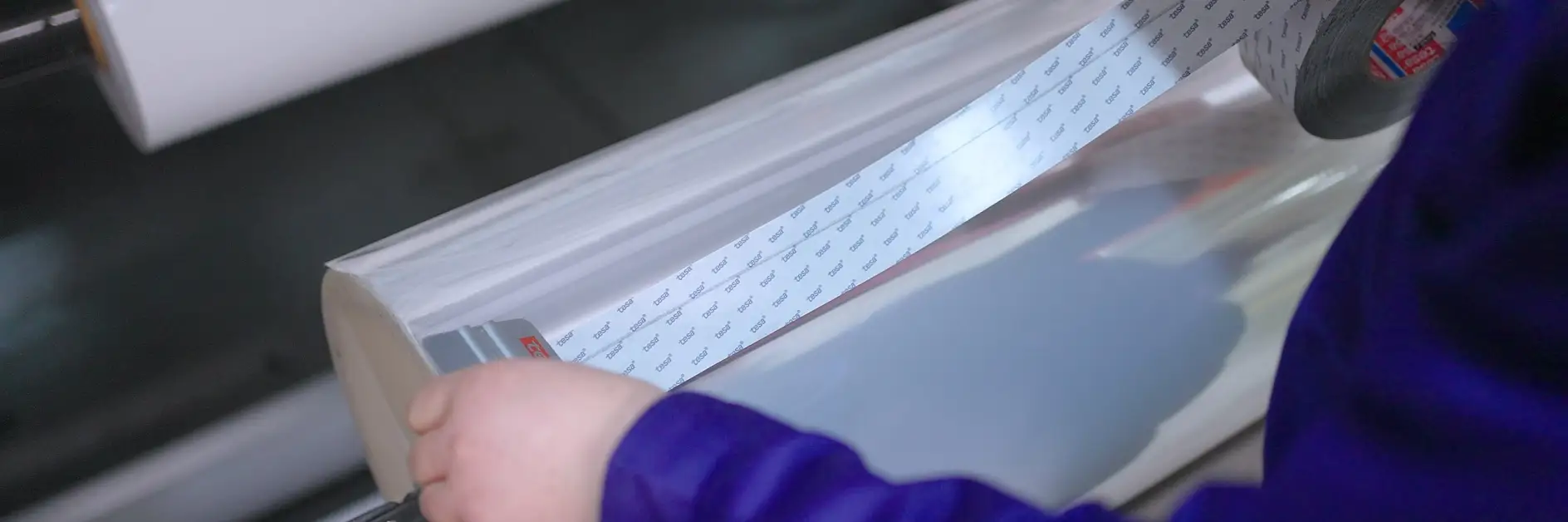

tesa® EasySplice flying splicing tape

During reel changes, we have used tesa® EasySplice flying splicing tape. It meets our splicing success rate on different materials and guarantees continuous production at high speed for CINOVA series.

Is there any sustainability practice that Huayang can share?

Our company uses ground source heat pumps for heating & cooling and solar power generation for power supply, which could reduce CO₂ emissions by 4000 tons per year.

© Huayang

Our CI flexo machine has used tesa® Twinlock self-adhesive sleeves and tesa® EasySplice flying splicing tape - these two solutions could help us simplify the plate mounting process, increase production efficiency, and reduce waste generation.

These are examples of our efforts to increase environmental protection. We are excited to collaborate with industry partners to continuously explore more sustainable flexo solutions!

Thanks a lot for the interview and we look forward to our future cooperation and to meeting you at drupa in May 2024!