Sustainability

With its thin 19 µm backing made from 85 % recycled PET, tesa® 60418 is a more sustainable and competitive packaging tape for mass production.

tesa® 60418 Thin recycled PET packaging tape

161 billion parcels were delivered in 20221, and a quarter of consumers say that sustainability will be their most important purchase criterion in the near future2. This means that sustainable packaging is an important trend, and we at tesa are committed to playing our part in the transition.

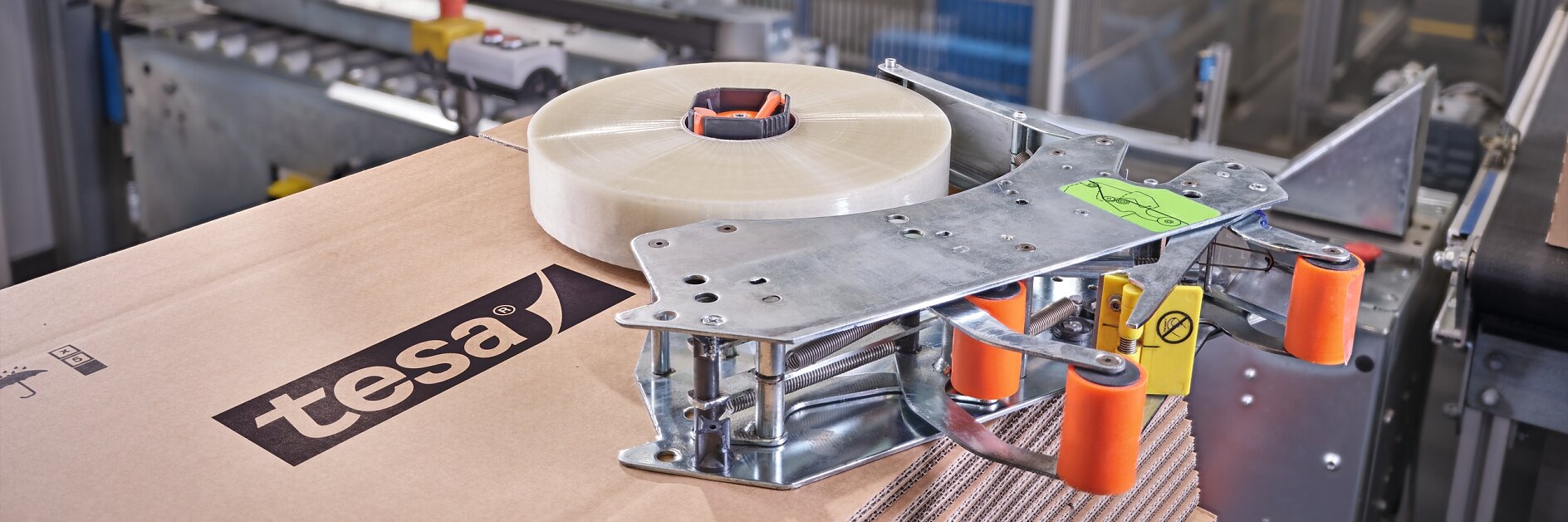

Our current range of more sustainable carton sealing tapes consists of film-based packaging tapes and paper-based packaging tapes. To offer an additional option for customers who are looking for a reliable yet competitive filmic tape, we have developed the new tesa® 60418 Thin recycled PET packaging tape. It covers volume applications with manual, semi-automated and automated tape dispensing and is ideal for medium sized cartons up to 25 kg.

The 19 µm thin backing of tesa® 60418 Thin recycled PET packaging tape consists of 85 % post-consumer PET waste, which reduces the need for new polymers accordingly. Thanks to the good mechanical properties of PET, the backing can be thinner than a BOPP or PVC backing without sacrificing performance.

Let’s make packaging easier!

We have developed the new tesa® 60418 Thin recycled PET packaging tape together with our customers to tailor it precisely to the needs of the industry. One of the most important requirements is, of course, easy application. That's why tesa® 60418 has a low unwinding force and a thin, flexible backing combined with a tacky adhesive.

The reduced thickness allows for long rolls of up to 1,500 metres in length, which are ideal for use in dispensers in semi-automated or automated packaging lines and literally go a long way before they must be changed. To support different packaging applications, tesa® 60418 is available in transparent, brown and white.

From a technical point of view, the new tesa® 60418 Thin recycled PET packaging tape impresses with an adhesion to steel of 6 N/cm, a tensile strength of 38 N/cm and an elongation at break of 120 %.