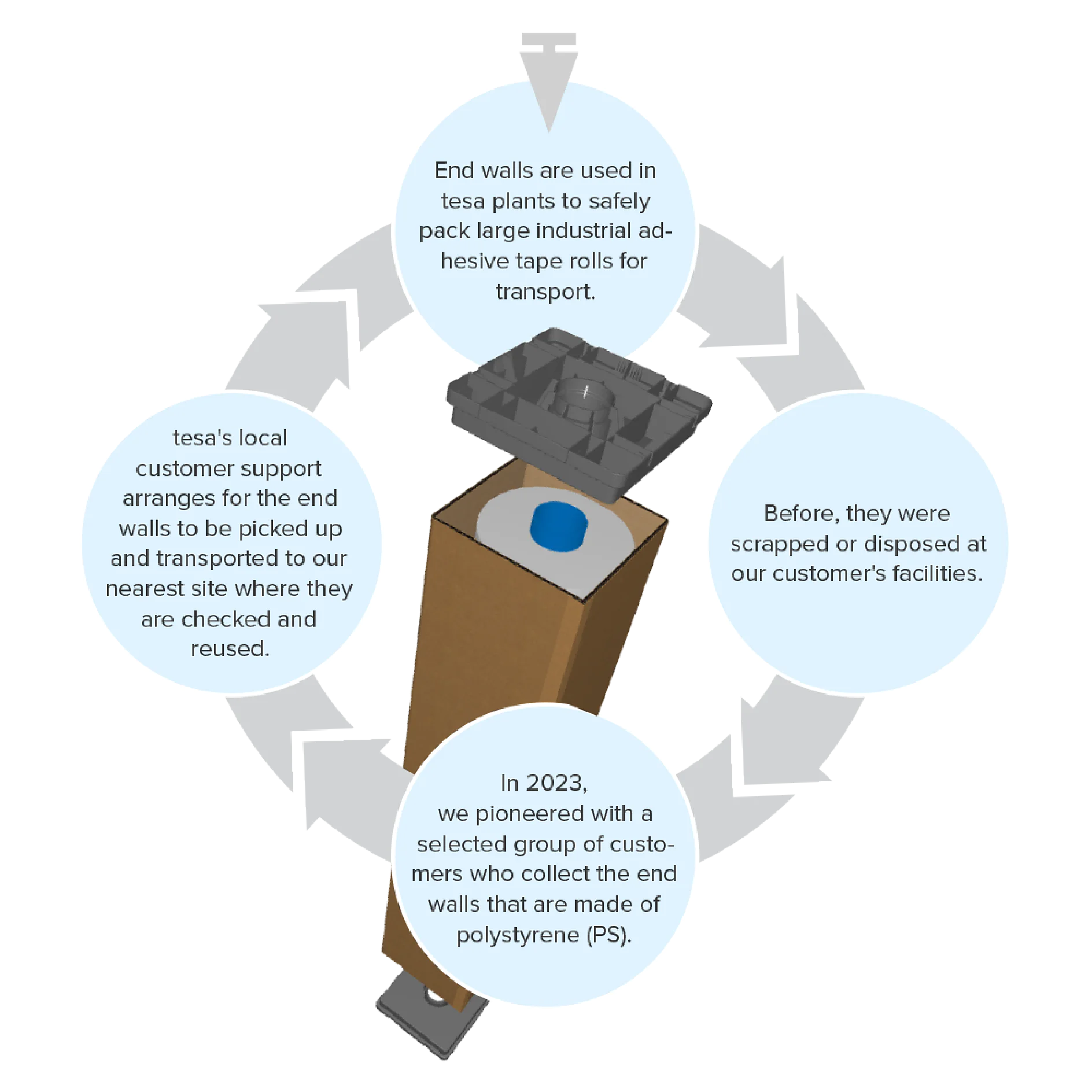

Out of sight, out of mind – will no longer apply. At least not for tesa, when it comes to the question of what happens to our high-quality packaging once the product it protects has safely arrived at our customers. In 2023, our HQ Packaging Development in collaboration with the local team at tesa site Suzhou started a pilot project: Hundreds of thousands of industrial adhesive tape roles, which are shipped from the warehouse in Shanghai to customers, could potentially be re-used in a cycle.

Back to the “beginning”: Reuse of polystyrene end walls

To ensure the safety and protection of our products, we utilize robust packaging made from high-quality materials for both storage and shipping purposes. The large industrial rolls of various heights are packed in slim cardboard sleeves and strapped the top and bottom with pure polystyrene (PS) end caps. A fully assembled package can weigh up to 70 kg, highlighting the essential durability of the chosen packaging materials. This durability is also an advantage for recyclability; high-quality PS elements exhibit minimal or no damage during transportation. "That's why we came up with the idea of establishing a circularity program for the polystyrene end walls made," explains Markus Neugart, Head of Packaging Development Industry. Experience has shown that the rejection rate during the sorting of used end walls is below 5 %.