Optically Clear Adhesive (OCA) is the preferred solution for automotive manufacturers around the world, for developing brilliant displays in vehicle cabins. Automotive displays are composed of more than a dozen layers of housing, cover lenses, display panels and mounting tapes. Our assortment covers adhesive solutions for various applications including lenses, touch panels and rigid-to-flexible or rigid-to-rigid substrates.

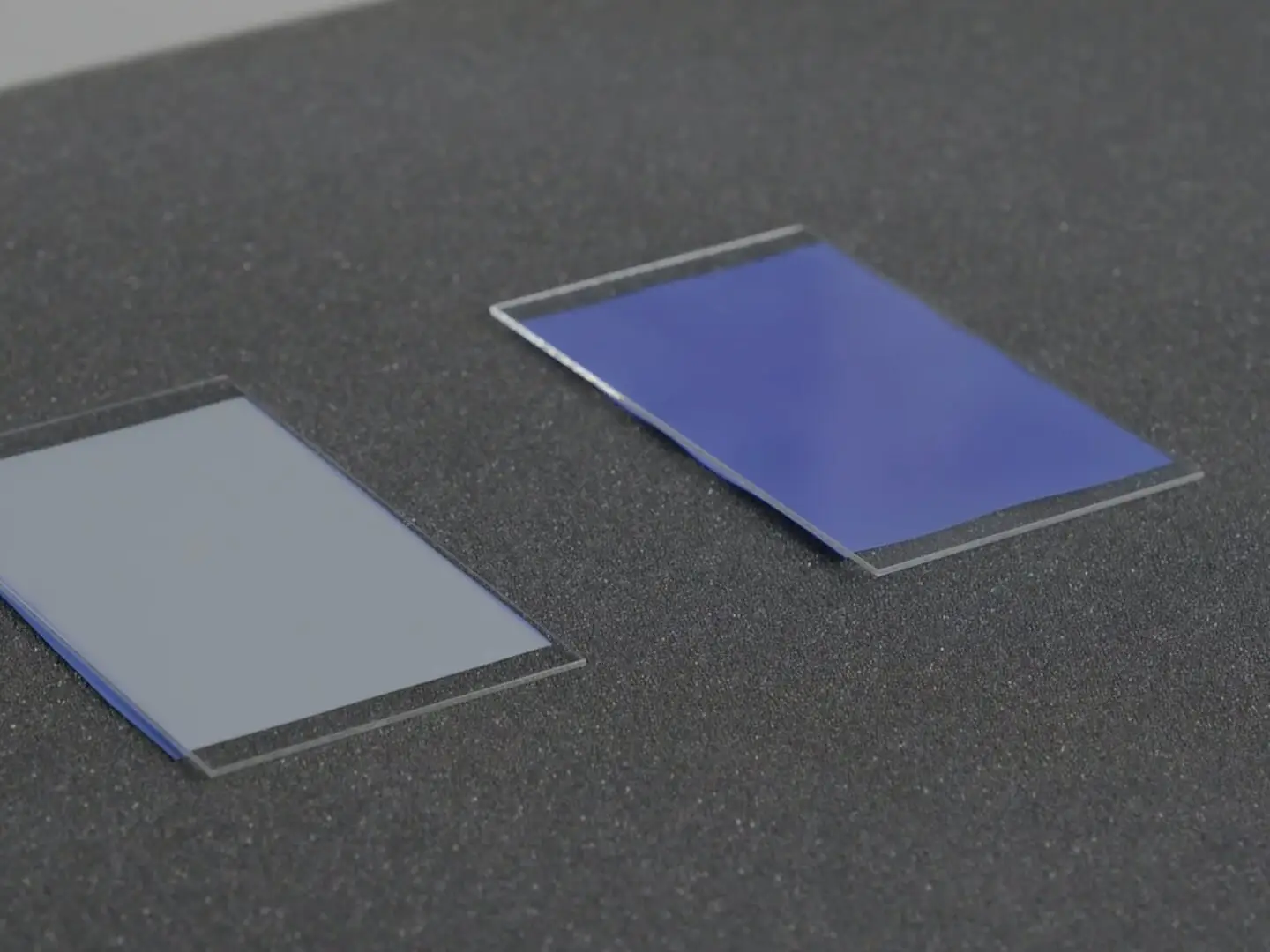

The special properties in OCA are designed to improve a display’s optical quality by preventing reflection from within the stack. OCA increases light transmission and improves contrast, giving brilliance to bright colors. It also offers essential protection for components against damage from overexposure to UV light, which results in a yellowing effect that not only weakens the optical quality of a display but also deteriorates its structure.

We offer a closer look at how yellowing is measured, and how it can be prevented in display technology.