Rotor Blade Finish

Permanent applications on rotor blades – discover our reliable adhesive tape solutions.

Permanent applications on rotor blades – discover our reliable adhesive tape solutions.

Leading Edge Protection

The leading edge of a blade is subject to erosion from heavy rain. Protect your blade with our single-sided PU tape. tesa® 52994 has proven itself in the wind energy, automotive and various other industries. A rain erosion test report is available upon request.

Product features:

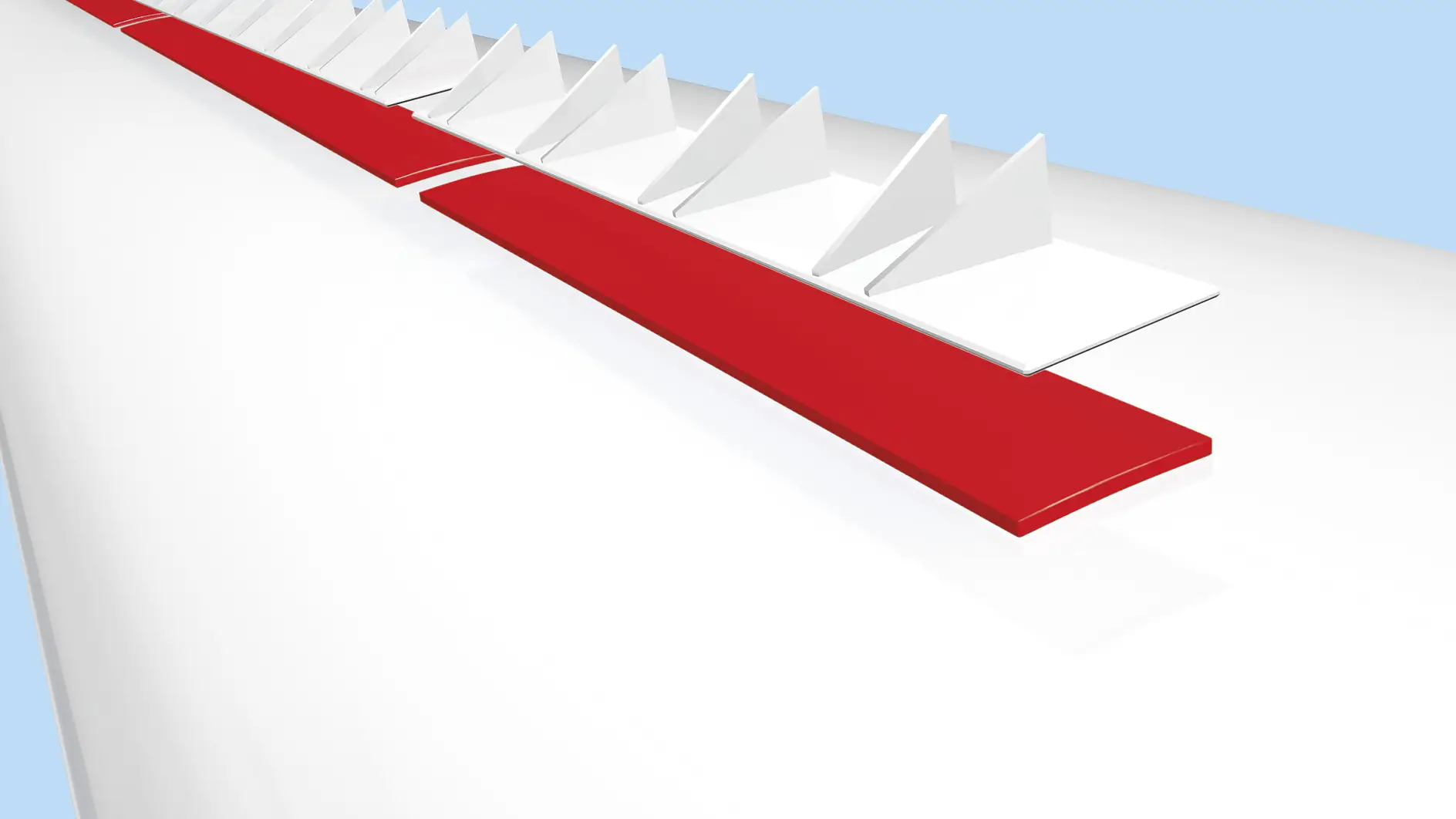

Mounting of Vortex Generators

In blade design, exterior attachment parts such as vortex generators or training edge serrations are used to optimise the turbine performance. Use double-sided tesa® ACXplus acrylic foam tapes for bonding and to optimise your production process during blade finishing.

Compared to liquid adhesive systems, our constructive bonding tapes are easy to use and build the bond quickly. This means that assembly time can be cut down significantly.

At the same time, tesa® ACXplus offers high bonding strength, stress-relaxing properties and excellent resistance to weathering. We can provide comprehensive technical literature and our laboratory specialising in adhesive application will help you during your design process.

Product features:

High bonding strength

Stress-relaxing properties

Resistant to weathering and ageing

Technical design values available

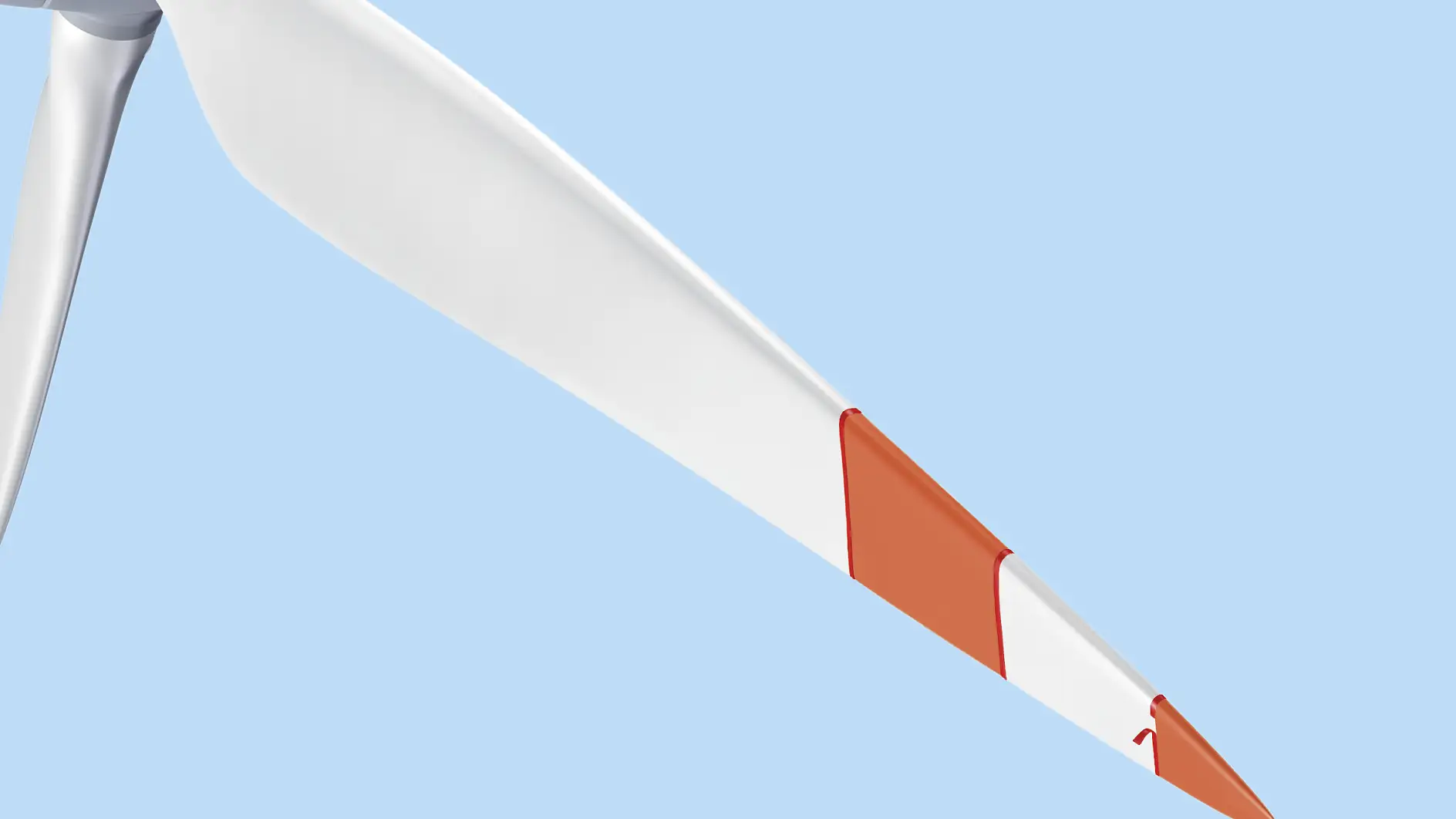

Spray Paint

The final touch on the wind turbine blade is the red paint at its tip. Whichever painting process is used – spray painting or other – we are experts in masking applications and have a wide variety of masking tapes that will facilitate your process: easy and fast to apply, secure adhesion to the substrate to make sure paint edges are sharp and clear, and easy to remove without leaving any residues on the blade.