OLED displays increase brilliance and provide a true black color. As our automotive partners incorporate them into increasingly complex display stacks, they are looking for methods to reduce the total number of steps in the production process.

UV block for

OLED displays

Creating an adhesive tape with UV block solution for OLED displays

tesa’s optically clear adhesive (OCA) products are the preferred choice for many leading manufacturers of automotive displays as they:

A view from the expert

We are confident that our adhesive products can assist automotive designers looking for the next leap in display tech. Our confidence is shared by industry experts such as Prof. Karlheinz Blankenbach.

Prof. Blankenbach is founder of the Display Lab at Pforzheim University, a leading research-oriented university of applied sciences in Germany. In the leading world-wide organization, the Society of Information Display, he holds prestigious positions on committees shaping the future of displays.

His work covers many aspects of automotive displays including environmental and lifetime degradation.

Together with colleagues, Prof. Blankenbach investigated the effects of UV damage on displays. They concluded that displays in demanding applications like automotive and digital signage need UV protection to increase lifespan.

At tesa we have taken this work further, combining it with the feedback of our customers to produce an optically clear adhesive with UV blocking properties. This OCA protects itself and the layers behind against the harmful impact of UV exposure. It means additional UV protection layers such as polarizers are no longer required.

The effects of UV protection on OLED displays

Electronic displays require protection from UV light. That is because, over time, UV light destroys organic materials in OLEDs and inorganic materials such as plastics in LCDs, microLEDs and OLEDs, and decreases their performance.

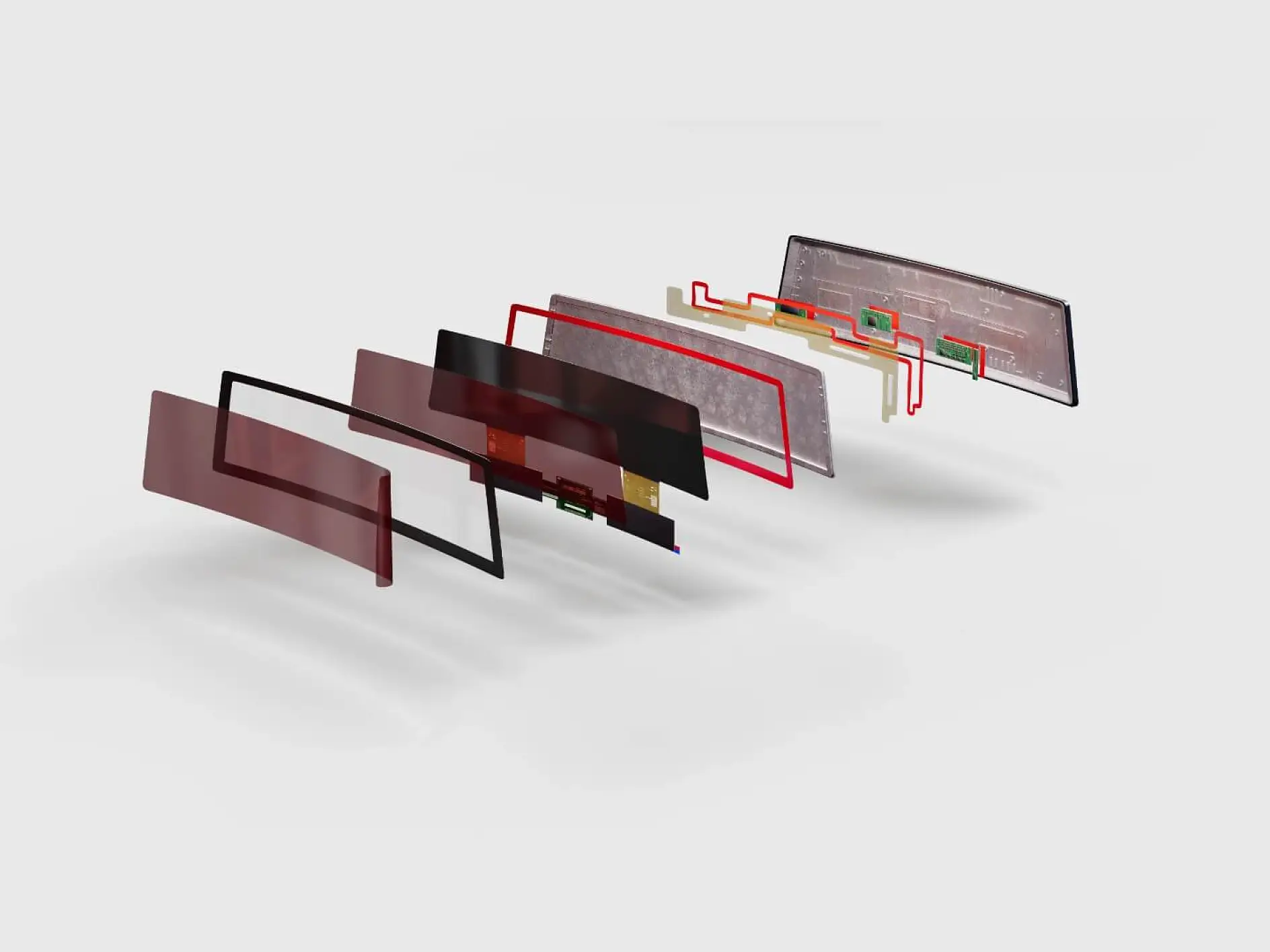

Testing on OLED displays with 500 hours of UV light exposure reveals that luminance decreases by less than one per cent when UV protection is applied, compared to a fall of 5 % in unprotected OLEDs. At a lower luminance, readability in bright light decreases on OLED displays, while a degraded polarizer reduces the contrast for LCDs. Therefore, when integrating displays into cars a proper UV light blocker is required to ensure its long term and high-quality use. The key challenge for engineers designing the optical display stack is finding the balance between effective UV light blocking and a very high transmission of visible light.

What our partners want

"Engineers want more flexibility in display architectures, to achieve even more innovative designs.”

- Prof. Blankenbach

With some changes to the structure of the display design, we believe we can give engineers that flexibility.

Integrating the UV block into the optically clear adhesive means there is no need for additional UV blocking layers such as coatings on polarizers. This in turn leads to a reduction of the total number of steps in the production process.

Furthermore, engineers prefer the blocking function to be the closest to the front lens. This offers secure protection for the OCA itself and all layers behind it – such as polarizers, touch sensors and especially sensitive OLED components – against harmful UV radiation.

With these requirements met, engineers can focus on new trends and make new designs such as curved or narrow frame displays happen.

Our solution – tesa® UV blocking OCA

tesa® OCA is a double-sided adhesive tape made of optical acrylic adhesive. Our OCA 88910 integrates a UV blocker additive, offering display protection against UV light in a very efficient way.

Testing and results

Samples of tesa® UV-blocking OCA 88910 were tested in a variety of challenging scenarios. We wanted to see how well the product performs the task of UV blocking, and how well it worked in tandem with other display layers.

“The OCA tape more than met manufacturer requirements for transmission and haze. The results would make for outstanding image quality on automotive displays.”

- Prof. Blankenbach

The UV blocker has been designed not to obscure visible light from being transmitted to the OCA, and block UV light. In fact, testing showed over 99 % of visible light transmissions passing through.

It means high brightness with hardly any loss due to the special UV protection integrated into the OCA.

Reliability tests such as lifetime and thermal stress were carefully set up to ensure the accuracy of the tape’s performance – all of which were passed successfully.

Under stringent testing conditions, our tesa® OCA 88910 has demonstrated its ability to block UV radiation while transmitting the relevant visible light, making it a valuable display component to an automotive industry that is always looking for ways to innovate.

Conclusion

Especially when working with OLED, manufacturers face many challenges as they seek to create cutting-edge screens for vehicles. But with our solution, backed by one of the world’s leading experts in display technology, we are confident we can help our partners reach new heights of automotive display design.

This piece was written in collaboration with Prof. Karlheinz Blankenbach, founder of the Display Lab at Pforzheim University.